Page 397 - Multidimensional Chromatography

P. 397

Multidimensional Chromatographic Applications in the Oil Industry 389

14.3.1 THE ANALYSIS OF BENZENE, TOLUENE AND HIGHER

AROMATICS IN LOW-BOILING FRACTIONS

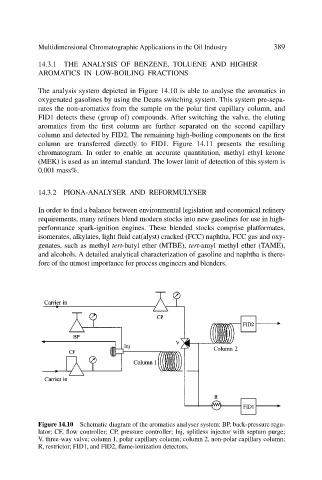

The analysis system depicted in Figure 14.10 is able to analyse the aromatics in

oxygenated gasolines by using the Deans switching system. This system pre-sepa-

rates the non-aromatics from the sample on the polar first capillary column, and

FID1 detects these (group of) compounds. After switching the valve, the eluting

aromatics from the first column are further separated on the second capillary

column and detected by FID2. The remaining high-boiling components on the first

column are transferred directly to FID1. Figure 14.11 presents the resulting

chromatogram. In order to enable an accurate quantitation, methyl ethyl ketone

(MEK) is used as an internal standard. The lower limit of detection of this system is

0.001 mass%.

14.3.2 PIONA-ANALYSER AND REFORMULYSER

In order to find a balance between environmental legislation and economical refinery

requirements, many refiners blend modern stocks into new gasolines for use in high-

performance spark-ignition engines. These blended stocks comprise platformates,

isomerates, alkylates, light fluid cat(alyst) cracked (FCC) naphtha, FCC gas and oxy-

genates, such as methyl tert-butyl ether (MTBE), tert-amyl methyl ether (TAME),

and alcohols. A detailed analytical characterization of gasoline and naphtha is there-

fore of the utmost importance for process engineers and blenders.

Figure 14.10 Schematic diagram of the aromatics analyser system: BP, back-pressure regu-

lator; CF, flow controller; CP, pressure controller; Inj, splitless injector with septum purge;

V, three-way valve; column 1, polar capillary column; column 2, non-polar capillary column;

R, restrictor; FID1, and FID2, flame-ionization detectors.