Page 348 - Book Hosokawa Nanoparticle Technology Handbook

P. 348

6.1 FUNCTIONALITY OF NANOSTRUCTURES AND THEIR CHARACTERISTIC EVALUATION

anti-corrosive parts such as bearings,

solid–liquid separation membrane,

Solid–gas separation membranes,

High-strength, heat-resistant and

environmental filters, etc.

Applications

Improvement of gas and liquid separation performance by

fabricating nanostructures (control of porous structure)

Improvement of mechanical strength such as strength,

fracture toughness, etc. by fabricating composite

Expected effects and performances

of particles by fabricating nanostructures)

nanostructures crushing media, turbine blades, etc. Performance of superplasticity by fabricating nanostructures (making defects smaller, suppressing crack growth and grain boundary control through the control of nanostructure) High thermal-conductivity parts such Improvement of thermal characteristics, such as thermal as substrates, thermal insulation, conductivity, thermal insulation, etc. by fabricating high-temperature parts, etc. nanostructures (control of phonon conductivity and thermal conductivity by fabricating nanostructures) Memory

• • • • • • • • •

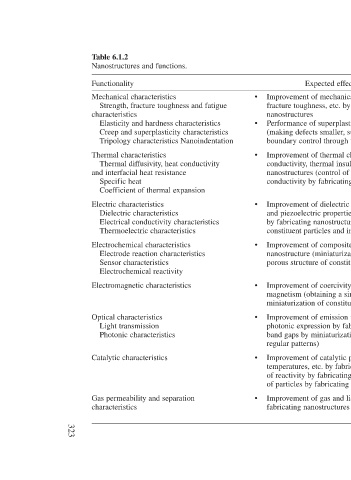

Nanostructures and functions. Mechanical characteristics Strength, fracture toughness and fatigue Elasticity and hardness characteristics Creep and superplasticity characteristics Tripology characteristics Nanoindentation Thermal characteristics Thermal diffusivity, heat conductivity and interfacial heat resistance Coefficient of thermal expansion Electric characteristics Dielectric characteristics Electrical conductivity characteristics Thermoelectric characteristics Electrochemical characteristics Electrode reaction characteristics Sensor characteristics E

Table 6.1.2 Functionality characteristics Specific heat characteristics

323