Page 502 - Book Hosokawa Nanoparticle Technology Handbook

P. 502

APPLICATIONS 14 BARIUM TITANATE NANOPARTICLES SYNTHESIS

The high-dielectric insulator using BaTiO was Heater

3

investigated by sol-gel routed film processing [5]. TC Thermocouple

However, since a precursor of BaTiO should be

3

heated at about 800 C to crystallize, substrates and

transistors were damaged by this heat treatment. MP2 TC

Tetragonal BaTiO particles are obtained by solid- TC

3

state reaction, but the size of these particles is in order Water

of several 10 m [3]. In hydrothermal synthesis, the TC Reactor tube

crystalline BaTiO particle is produced by hydrother-

3

mal treatment at 100–150 C from barium hydroxide MP1

and titanium dioxide with high alkali concentration

[4, 5]. Although particles several 10 nm in diameter Cooler

could be produced, some hydroxyl groups remained

Ba(OH) 2

inside or on the surface of the particle and thus the

crystalline degree of the hydroxide is not necessarily Filter

high [6]. This resulted from low reaction temperature

and high alkali concentration. In this way, nanosized Back-pressure

BaTiO particles with high crystalline degree could regulator

3

not be obtained by any methods.

Tetragonal BaTiO nanoparticles have been synthe- TiO sols

2

3

sized using supercritical water [7]. The features of

hydrothermal reaction under supercritical conditions Figure 14.1

are ability to control ionic reaction and metal oxide Continuous equipment to produce barium titanate

solubility in water; these are determining factors of nanoparticles.

particle formation on hydrothermal synthesis, by

changing temperature and pressure. Especially, when

hydrothermal crystallization takes place near the reaction occurs and metal oxide particle are formed.

critical point of water, nucleation occurs at a high The reactants are cooled and then the products are

degree of supersaturation and then nanoscaled parti- captured in the inline filter (pore size: 500 nm). The

cles can be produced. This resulted from an enhance- reactant is recovered in a vessel followed by depres-

ment of ionic reaction rate and an extremely low surization. Reaction temperatures were 300–420 C,

solubility of metal oxide (product) in water due to and pressures were 20–40 MPa. The collected parti-

decrease of dielectric constant of water [8]. Here, cles were dried in an oven at 60 C for 24 h. Crystal

selective production of tetragonal BaTiO nanoparti- structure and phase were determined by an X-ray

3

cles by hydrothermal synthesis in supercritical water diffraction method and Raman spectroscopy.

using a flow reactor is described. Morphologies and size of particles were observed by

a transmission electron microscopy.

1. Experiment for producing tetragonal BaTiO 3 2. Selective production of tetragonal BaTiO 3

nanoparticles by supercritical hydrothermal synthesis

In order to determine the appropriate solution condi-

Titanium oxide sol was used as a source of titanium. tion for producing BaTiO , we conducted several

3

Barium hydroxide was used as a source of barium. In preparatory experiments at 400 C, 30 MPa. The Ba/Ti

the cases to investigate the effect of Ba/Ti molar ratio molar ratio was changed in the range of 1–10 under

of starting solution and pH, sodium hydroxide was various NaOH concentrations from 0.02 to 0.2 M. As

used as pH controller. a result, BaTiO was obtained from barium-rich

3

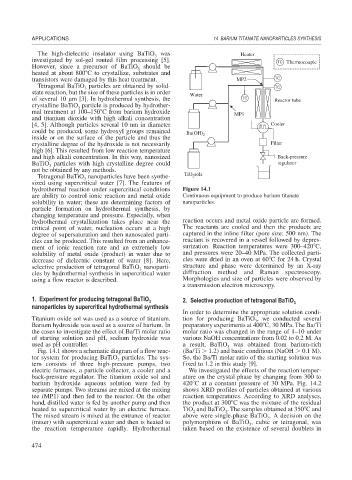

Fig. 14.1 shows a schematic diagram of a flow reac- (Ba/Ti 1.2) and basic conditions (NaOH 0.1 M).

tor system for producing BaTiO particles. The sys- So, the Ba/Ti molar ratio of the starting solution was

3

tem consists of three high-pressure pumps, two fixed to 1.2 in this study [9].

electric furnaces, a particle collector, a cooler and a We investigated the effects of the reaction temper-

back-pressure regulator. The titanium oxide sol and ature on the crystal phase by changing from 300 to

barium hydroxide aqueous solution were fed by 420 C at a constant pressure of 30 MPa. Fig. 14.2

separate pumps. Two streams are mixed at the mixing shows XRD profiles of particles obtained at various

tee (MP1) and then fed to the reactor. On the other reaction temperatures. According to XRD analyses,

hand, distilled water is fed by another pump and then the product at 300 C was the mixture of the residual

heated to supercritical water by an electric furnace. TiO and BaTiO . The samples obtained at 350 C and

2

3

The mixed stream is mixed at the entrance of reactor above were single-phase BaTiO . A decision on the

3

(mixer) with supercritical water and then is heated to polymorphism of BaTiO , cubic or tetragonal, was

3

the reaction temperature rapidly. Hydrothermal taken based on the existence of several doublets in

474