Page 14 - Nanotechnology an introduction

P. 14

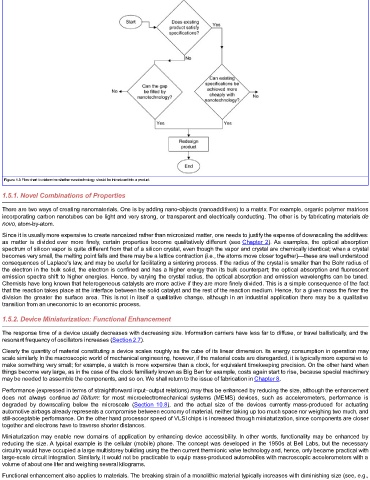

Figure 1.3 Flow chart to determine whether nanotechnology should be introduced into a product.

1.5.1. Novel Combinations of Properties

There are two ways of creating nanomaterials. One is by adding nano-objects (nanoadditives) to a matrix. For example, organic polymer matrices

incorporating carbon nanotubes can be light and very strong, or transparent and electrically conducting. The other is by fabricating materials de

novo, atom-by-atom.

Since it is usually more expensive to create nanosized rather than microsized matter, one needs to justify the expense of downscaling the additives:

as matter is divided ever more finely, certain properties become qualitatively different (see Chapter 2). As examples, the optical absorption

spectrum of silicon vapor is quite different from that of a silicon crystal, even though the vapor and crystal are chemically identical; when a crystal

becomes very small, the melting point falls and there may be a lattice contraction (i.e., the atoms move closer together)—these are well understood

consequences of Laplace's law, and may be useful for facilitating a sintering process. If the radius of the crystal is smaller than the Bohr radius of

the electron in the bulk solid, the electron is confined and has a higher energy than its bulk counterpart; the optical absorption and fluorescent

emission spectra shift to higher energies. Hence, by varying the crystal radius, the optical absorption and emission wavelengths can be tuned.

Chemists have long known that heterogeneous catalysts are more active if they are more finely divided. This is a simple consequence of the fact

that the reaction takes place at the interface between the solid catalyst and the rest of the reaction medium. Hence, for a given mass the finer the

division the greater the surface area. This is not in itself a qualitative change, although in an industrial application there may be a qualitative

transition from an uneconomic to an economic process.

1.5.2. Device Miniaturization: Functional Enhancement

The response time of a device usually decreases with decreasing size. Information carriers have less far to diffuse, or travel ballistically, and the

resonant frequency of oscillators increases (Section 2.7).

Clearly the quantity of material constituting a device scales roughly as the cube of its linear dimension. Its energy consumption in operation may

scale similarly. In the macroscopic world of mechanical engineering, however, if the material costs are disregarded, it is typically more expensive to

make something very small; for example, a watch is more expensive than a clock, for equivalent timekeeping precision. On the other hand when

things become very large, as in the case of the clock familiarly known as Big Ben for example, costs again start to rise, because special machinery

may be needed to assemble the components, and so on. We shall return to the issue of fabrication in Chapter 8.

Performance (expressed in terms of straightforward input–output relations) may thus be enhanced by reducing the size, although the enhancement

does not always continue ad libitum: for most microelectromechanical systems (MEMS) devices, such as accelerometers, performance is

degraded by downscaling below the microscale (Section 10.8), and the actual size of the devices currently mass-produced for actuating

automotive airbags already represents a compromise between economy of material, neither taking up too much space nor weighing two much, and

still-acceptable performance. On the other hand processor speed of VLSI chips is increased through miniaturization, since components are closer

together and electrons have to traverse shorter distances.

Miniaturization may enable new domains of application by enhancing device accessibility. In other words, functionality may be enhanced by

reducing the size. A typical example is the cellular (mobile) phone. The concept was developed in the 1950s at Bell Labs, but the necessary

circuitry would have occupied a large multistorey building using the then current thermionic valve technology and, hence, only became practical with

large-scale circuit integration. Similarly, it would not be practicable to equip mass-produced automobiles with macroscopic accelerometers with a

volume of about one liter and weighing several kilograms.

Functional enhancement also applies to materials. The breaking strain of a monolithic material typically increases with diminishing size (see, e.g.,