Page 62 - Nanotechnology an introduction

P. 62

Chapter Contents

6.1 Nanoparticles 103

6.1.1 Comminution and Dispersion 104

6.1.2 Nucleation and Growth 104

6.2 Nanofibers 108

6.3 Nanoplates and Ultrathin Coatings 108

6.3.1 Molecular Beam Epitaxy (MBE) 109

6.3.2 Langmuir Films 109

6.3.3 Self-Assembled Monolayers (SAMs) 113

6.4 Crystallization and Supramolecular Chemistry 114

6.5 Composites 115

6.5.1 Polymer–Nano-Object Blends 116

6.5.2 Metal–Matrix Composites 119

6.5.3 Self-Repairing Composites 120

6.5.4 Nanofluids for Thermal Transport 121

6.5.5 Alternating Polyelectrolyte Deposition 122

6.6 Summary 124

6.7 Further Reading 124

The two main divisions of nanomaterials are nano-objects and nanostructured materials. The various kinds of nano-objects (particles, fibers and plates) are described, along with their methods of manufacture. The most important

nanostructured materials are currently nanocomposites. Their fabrication and applications are discussed. Wetting of the embedded nano-objects by their matrix is of crucial importance; present synthetic capabilities reveal themselves as far

inferior to what nature can do. Composites with enhanced mechanical properties require careful consideration of how load is transferred between matrix and particle or fiber, and how many cycles of repeated loading and unloading fatigue the

material.

Keywords: terminology, nano-objects, nanoparticles, nanofibers, nanoplates, nanocomposites, molecular beam epitaxy, Langmuir–Blodgett films, alternating polyelectrolyte deposition

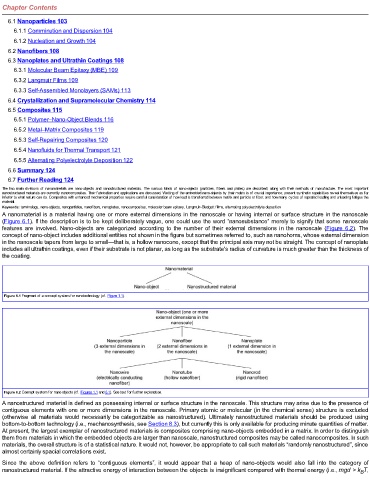

A nanomaterial is a material having one or more external dimensions in the nanoscale or having internal or surface structure in the nanoscale

(Figure 6.1). If the description is to be kept deliberately vague, one could use the word “nanosubstance” merely to signify that some nanoscale

features are involved. Nano-objects are categorized according to the number of their external dimensions in the nanoscale (Figure 6.2). The

concept of nano-object includes additional entities not shown in the figure but sometimes referred to, such as nanohorns, whose external dimension

in the nanoscale tapers from large to small—that is, a hollow nanocone, except that the principal axis may not be straight. The concept of nanoplate

includes all ultrathin coatings, even if their substrate is not planar, as long as the substrate's radius of curvature is much greater than the thickness of

the coating.

Figure 6.1 Fragment of a concept system for nanotechnology (cf. Figure 1.1).

Figure 6.2 Concept system for nano-objects (cf. Figures 1.1 and 6.1). See text for further explanation.

A nanostructured material is defined as possessing internal or surface structure in the nanoscale. This structure may arise due to the presence of

contiguous elements with one or more dimensions in the nanoscale. Primary atomic or molecular (in the chemical sense) structure is excluded

(otherwise all materials would necessarily be categorizable as nanostructured). Ultimately nanostructured materials should be produced using

bottom-to-bottom technology (i.e., mechanosynthesis, see Section 8.3), but currently this is only available for producing minute quantities of matter.

At present, the largest exemplar of nanostructured materials is composites comprising nano-objects embedded in a matrix. In order to distinguish

them from materials in which the embedded objects are larger than nanoscale, nanostructured composites may be called nanocomposites. In such

materials, the overall structure is of a statistical nature. It would not, however, be appropriate to call such materials “randomly nanostructured”, since

almost certainly spacial correlations exist.

Since the above definition refers to “contiguous elements”, it would appear that a heap of nano-objects would also fall into the category of

nanostructured material. If the attractive energy of interaction between the objects is insignificant compared with thermal energy (i.e., mgd > k T,

B