Page 74 - New Trends In Coal Conversion

P. 74

40 New Trends in Coal Conversion

selectivity of 100% over N 2 and generates electricity. CEPACS will be demonstrated

at 3 MW e scale on real coal flue gas at James M. Barry Electric Generating Station in

Alabama in 2018. The pilot plant is designed to capture 90% of the inlet CO 2 produc-

ing 67 t/d of CO 2 and 1,178 kW. A technoeconomic analysis carried out for a 550 MW

supercritical coal-fired power plant points out that 4.3 Mt CO 2 /y could be captured at a

90% capture rate with a plant efficiency of 40.7%, which is higher than that without

capture (Ghezel-Ayagh, 2017).

2.3 Oxy-combustion capture in coal power plants

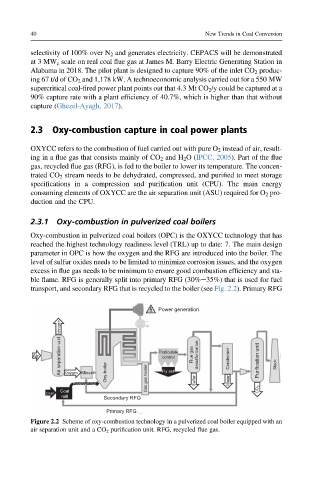

OXYCC refers to the combustion of fuel carried out with pure O 2 instead of air, result-

ing in a flue gas that consists mainly of CO 2 and H 2 O(IPCC, 2005). Part of the flue

gas, recycled flue gas (RFG), is fed to the boiler to lower its temperature. The concen-

trated CO 2 stream needs to be dehydrated, compressed, and purified to meet storage

specifications in a compression and purification unit (CPU). The main energy

consuming elements of OXYCC are the air separation unit (ASU) required for O 2 pro-

duction and the CPU.

2.3.1 Oxy-combustion in pulverized coal boilers

Oxy-combustion in pulverized coal boilers (OPC) is the OXYCC technology that has

reached the highest technology readiness level (TRL) up to date: 7. The main design

parameter in OPC is how the oxygen and the RFG are introduced into the boiler. The

level of sulfur oxides needs to be limited to minimize corrosion issues, and the oxygen

excess in flue gas needs to be minimum to ensure good combustion efficiency and sta-

ble flame. RFG is generally split into primary RFG (30%e35%) that is used for fuel

transport, and secondary RFG that is recycled to the boiler (see Fig. 2.2). Primary RFG

Power generation

Nitrogen

Air separation unit control Condenser Purification unit Stack

Air Particulate Flue gas desulfurization

Oxygen Mixer

Pulverized coal Oxy-boiler Gas gas heater Fly ash Sulfur Water

Coal CO 2

Coal

mill Secondary RFG

Primary RFG

Figure 2.2 Scheme of oxy-combustion technology in a pulverized coal boiler equipped with an

air separation unit and a CO 2 purification unit. RFG, recycled flue gas.