Page 79 - New Trends In Coal Conversion

P. 79

Current status of CO 2 capture from coal facilities 45

Heat recovery

steam generator

Power

Hot exhaust

generation

Steam turbine

Combustion

Nitrogen Air chamber Gas Power

turbine

Air separation unit Particulate Sulfur removal WGS CO 2 capture generation

Air control Water

Gasifier

wash

Fly ash

Oxygen

Sulfur Steam Stack

Coal

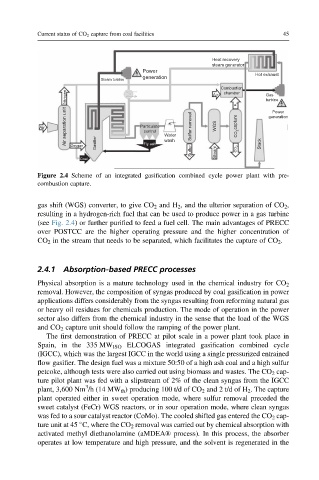

Figure 2.4 Scheme of an integrated gasification combined cycle power plant with pre-

combustion capture.

gas shift (WGS) converter, to give CO 2 and H 2 , and the ulterior separation of CO 2 ,

resulting in a hydrogen-rich fuel that can be used to produce power in a gas turbine

(see Fig. 2.4) or further purified to feed a fuel cell. The main advantages of PRECC

over POSTCC are the higher operating pressure and the higher concentration of

CO 2 in the stream that needs to be separated, which facilitates the capture of CO 2 .

2.4.1 Absorption-based PRECC processes

Physical absorption is a mature technology used in the chemical industry for CO 2

removal. However, the composition of syngas produced by coal gasification in power

applications differs considerably from the syngas resulting from reforming natural gas

or heavy oil residues for chemicals production. The mode of operation in the power

sector also differs from the chemical industry in the sense that the load of the WGS

and CO 2 capture unit should follow the ramping of the power plant.

The first demonstration of PRECC at pilot scale in a power plant took place in

Spain, in the 335 MW ISO ELCOGAS integrated gasification combined cycle

(IGCC), which was the largest IGCC in the world using a single pressurized entrained

flow gasifier. The design fuel was a mixture 50:50 of a high ash coal and a high sulfur

petcoke, although tests were also carried out using biomass and wastes. The CO 2 cap-

ture pilot plant was fed with a slipstream of 2% of the clean syngas from the IGCC

3

plant, 3,600 Nm /h (14 MW th ) producing 100 t/d of CO 2 and 2 t/d of H 2 . The capture

plant operated either in sweet operation mode, where sulfur removal preceded the

sweet catalyst (FeCr) WGS reactors, or in sour operation mode, where clean syngas

was fed to a sour catalyst reactor (CoMo). The cooled shifted gas entered the CO 2 cap-

ture unit at 45 C, where the CO 2 removal was carried out by chemical absorption with

activated methyl diethanolamine (aMDEA® process). In this process, the absorber

operates at low temperature and high pressure, and the solvent is regenerated in the