Page 82 - New Trends In Coal Conversion

P. 82

48 New Trends in Coal Conversion

cleanup. The process operates at high temperature and pressure: 350e500 C and

10e50 bar. Moreover, SEWGS maximizes H 2 production by the simultaneous

removal of CO 2 . Potassium-promoted hydrotalcite presents high CO 2 capture capacity

at 400 C, catalytic activity for the WGS reaction, and excellent chemical and mechan-

þ

ical stability, being an ideal candidate for SEWGS. ALKASORB sorbent was devel-

oped in the framework of the European FP7 CAESAR project. SEWGS has been

demonstrated at bench scale (25 kW th ) with technical gases in a unit with 6 reactors

at the Energy Research Centre of the Netherlands. The results were used to validate

a simulation model that was later used to evaluate the upscale of the process to a

full IGCC plant. The resulting cost, 23 V/t CO 2 , for a capture rate of 90%, is consid-

erably lower than the Selexol case. The estimated energy consumption for this process

is 2.1 GJ/t CO 2 (Jansen et al., 2013).

2.5 CO capture in coal-based industrial processes

2

2.5.1 CO 2 capture in coal-to-chemicals industry

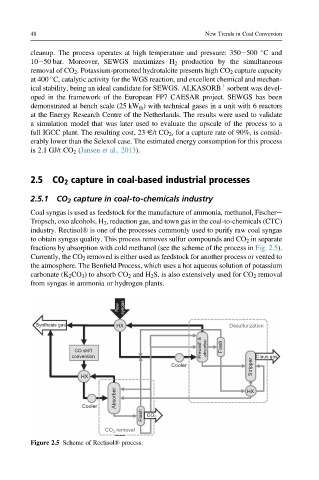

Coal syngas is used as feedstock for the manufacture of ammonia, methanol, Fischere

Tropsch, oxo alcohols, H 2 , reduction gas, and town gas in the coal-to-chemicals (CTC)

industry. Rectisol® is one of the processes commonly used to purify raw coal syngas

to obtain syngas quality. This process removes sulfur compounds and CO 2 in separate

fractions by absorption with cold methanol (see the scheme of the process in Fig. 2.5).

Currently, the CO 2 removed is either used as feedstock for another process or vented to

the atmosphere. The Benfield Process, which uses a hot aqueous solution of potassium

carbonate (K 2 CO 3 ) to absorb CO 2 and H 2 S, is also extensively used for CO 2 removal

from syngas in ammonia or hydrogen plants.

Raw syngas

Synthesis gas HX Desulfurization

Prewash & absorber Flash

CO shift

conversion

Stripper Claus gas

Cooler

HX

Absorber HX

Cooler

Flash CO 2

CO 2 removal

Figure 2.5 Scheme of Rectisol® process.