Page 84 - New Trends In Coal Conversion

P. 84

50 New Trends in Coal Conversion

generation, as a source of carbon for addition in steel making processes, and in direct

smelting of iron processes. Approximately 0.44 Mt of coal are required per Mt of steel

produced.

The iron and steel sector is one of the major CO 2 stationary emitters out of the

power sector where CCS could be installed contributing significantly to the mitigation

effort. The majority of CO 2 emissions arise from the coal consumption in the blast

furnace, although there are other large sources of CO 2 in a steel plant: the internal

power plant, the hot blast stove, the coke oven, etc. Toshiba analyzed the feasibility

of retrofitting a Chinese steel plant to supply 300 t/d of CO 2 for EOR in a nearby

oil field using chemical absorption. Hot blast stove flue gas was identified as the

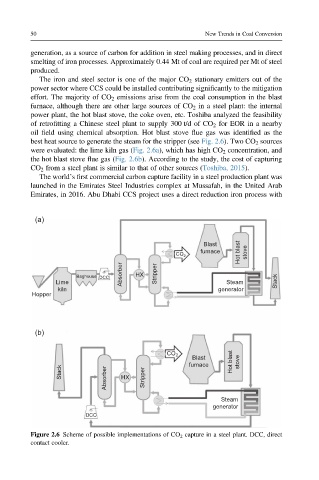

best heat source to generate the steam for the stripper (see Fig. 2.6). Two CO 2 sources

were evaluated: the lime kiln gas (Fig. 2.6a), which has high CO 2 concentration, and

the hot blast stove flue gas (Fig. 2.6b). According to the study, the cost of capturing

CO 2 from a steel plant is similar to that of other sources (Toshiba, 2015).

The world’s first commercial carbon capture facility in a steel production plant was

launched in the Emirates Steel Industries complex at Mussafah, in the United Arab

Emirates, in 2016. Abu Dhabi CCS project uses a direct reduction iron process with

(a)

Blast

furnace Hot blast stove

CO 2

Absorber HX Stripper

Baghouse DCC

Lime Steam Stack

kiln generator

Hopper

(b)

CO 2

Blast Hot blast stove

furnace

Stack Absorber HX Stripper

Steam

generator

DCC

Figure 2.6 Scheme of possible implementations of CO 2 capture in a steel plant. DCC, direct

contact cooler.