Page 161 - New Trends in Eco efficient and Recycled Concrete

P. 161

Sewage sludge ash 133

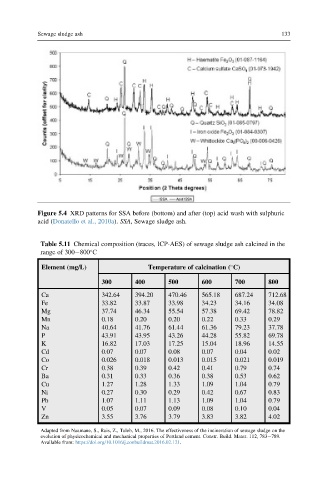

Figure 5.4 XRD patterns for SSA before (bottom) and after (top) acid wash with sulphuric

acid (Donatello et al., 2010a). SSA, Sewage sludge ash.

Table 5.11 Chemical composition (traces, ICP-AES) of sewage sludge ash calcined in the

range of 300 800 C

Element (mg/L) Temperature of calcination ( C)

300 400 500 600 700 800

Ca 342.64 394.20 470.46 565.18 687.24 712.68

Fe 33.82 33.87 33.98 34.23 34.16 34.08

Mg 37.74 46.34 55.54 57.38 69.42 78.82

Mn 0.18 0.20 0.20 0.22 0.33 0.29

Na 40.64 41.76 61.44 61.36 79.23 37.78

P 43.91 43.95 43.26 44.28 55.82 69.78

K 16.82 17.03 17.25 15.04 18.96 14.55

Cd 0.07 0.07 0.08 0.07 0.04 0.02

Co 0.026 0.018 0.013 0.015 0.021 0.019

Cr 0.38 0.39 0.42 0.41 0.79 0.74

Ba 0.31 0.33 0.36 0.38 0.53 0.62

Cu 1.27 1.28 1.33 1.09 1.04 0.79

Ni 0.27 0.30 0.29 0.42 0.67 0.83

Pb 1.07 1.11 1.13 1.09 1.04 0.79

V 0.05 0.07 0.09 0.08 0.10 0.04

Zn 3.55 3.76 3.79 3.83 3.82 4.02

Adapted from Naamane, S., Rais, Z., Taleb, M., 2016. The effectiveness of the incineration of sewage sludge on the

evolution of physicochemical and mechanical properties of Portland cement. Constr. Build. Mater. 112, 783 789.

Available from: https://doi.org/10.1016/j.conbuildmat.2016.02.121.