Page 244 - New Trends in Eco efficient and Recycled Concrete

P. 244

212 New Trends in Eco-efficient and Recycled Concrete

Production of Production of

fuels and

electricity raw materials

Production of

Production of

fuels and raw materials Primary Iron blast

Primary electricity production furnace Iron

production transformation

Production of Coal fired Production of Slag

water power plant Bottom ash water granulation

Steel

Electrical

Treatment power network Treatment Drying

Drying

Electricity

Grinding

Stock

Stock

Fly ash GBFS

Extraction of raw

materials

Primary

production

Production of fuels Combustion in the Si-metal

and energy electric arc oven

Treatment

Stock

Silica fume

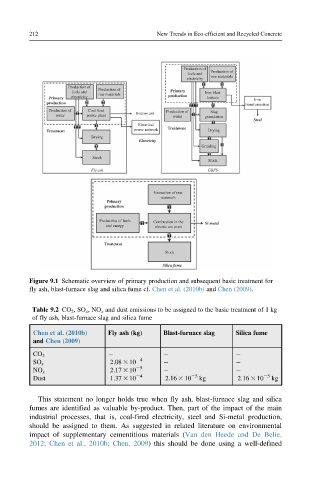

Figure 9.1 Schematic overview of primary production and subsequent basic treatment for

fly ash, blast-furnace slag and silica fume cf. Chen et al. (2010b) and Chen (2009).

Table 9.2 CO 2 ,SO x ,NO x and dust emissions to be assigned to the basic treatment of 1 kg

of fly ash, blast-furnace slag and silica fume

Chen et al. (2010b) Fly ash (kg) Blast-furnace slag Silica fume

and Chen (2009)

CO 2

2.08 3 10 24

SO x

2.17 3 10 25

NO x

Dust 1.37 3 10 24 2.16 3 10 25 kg 2.16 3 10 25 kg

This statement no longer holds true when fly ash, blast-furnace slag and silica

fumes are identified as valuable by-product. Then, part of the impact of the main

industrial processes, that is, coal-fired electricity, steel and Si-metal production,

should be assigned to them. As suggested in related literature on environmental

impact of supplementary cementitious materials (Van den Heede and De Belie,

2012; Chen et al., 2010b; Chen, 2009) this should be done using a well-defined