Page 419 - New Trends in Eco efficient and Recycled Concrete

P. 419

Application of alkali-activated industrial waste 373

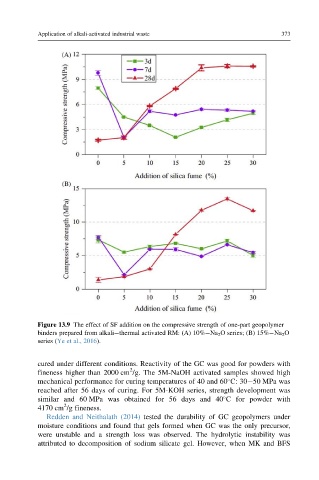

Figure 13.9 The effect of SF addition on the compressive strength of one-part geopolymer

binders prepared from alkali thermal activated RM: (A) 10% Na 2 O series; (B) 15% Na 2 O

series (Ye et al., 2016).

cured under different conditions. Reactivity of the GC was good for powders with

2

fineness higher than 2000 cm /g. The 5M-NaOH activated samples showed high

mechanical performance for curing temperatures of 40 and 60 C: 30 50 MPa was

reached after 56 days of curing. For 5M-KOH series, strength development was

similar and 60 MPa was obtained for 56 days and 40 C for powder with

2

4170 cm /g fineness.

Redden and Neithalath (2014) tested the durability of GC geopolymers under

moisture conditions and found that gels formed when GC was the only precursor,

were unstable and a strength loss was observed. The hydrolytic instability was

attributed to decomposition of sodium silicate gel. However, when MK and BFS