Page 59 - New Trends in Eco efficient and Recycled Concrete

P. 59

Biomass fly ash and biomass bottom ash 35

most limiting chemical factors which determine its possible real applications were

analysed. In this case, BBA from olive waste was studied in the Andalusian region,

Spain, since in this area large amounts of this type of biomass are used in BTPP.

Olive waste used in the production of this BBA were: olive cake, olive tree and, in

some cases, pine or poplar waste. These were added in the mix of biomass to be

burned.

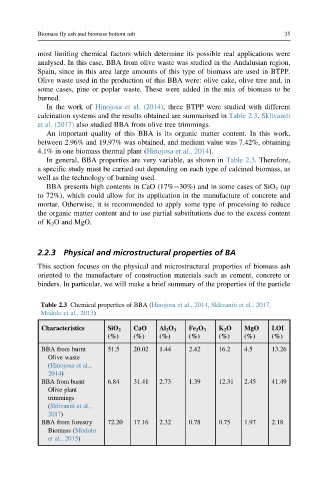

In the work of Hinojosa et al. (2014), three BTPP were studied with different

calcination systems and the results obtained are summarised in Table 2.3. Sklivaniti

et al. (2017) also studied BBA from olive tree trimmings.

An important quality of this BBA is its organic matter content. In this work,

between 2.96% and 19.97% was obtained, and medium value was 7.42%, obtaining

4.1% in one biomass thermal plant (Hinojosa et al., 2014).

In general, BBA properties are very variable, as shown in Table 2.3. Therefore,

a specific study must be carried out depending on each type of calcined biomass, as

well as the technology of burning used.

BBA presents high contents in CaO (17% 30%) and in some cases of SiO 2 (up

to 72%), which could allow for its application in the manufacture of concrete and

mortar. Otherwise, it is recommended to apply some type of processing to reduce

the organic matter content and to use partial substitutions due to the excess content

of K 2 O and MgO.

2.2.3 Physical and microstructural properties of BA

This section focuses on the physical and microstructural properties of biomass ash

oriented to the manufacture of construction materials such as cement, concrete or

binders. In particular, we will make a brief summary of the properties of the particle

Table 2.3 Chemical properties of BBA (Hinojosa et al., 2014, Sklivaniti et al., 2017,

Modolo et al., 2013)

Characteristics SiO 2 CaO Al 2 O 3 Fe 2 O 3 K 2 O MgO LOI

(%) (%) (%) (%) (%) (%) (%)

BBA from burnt 51.5 20.02 1.44 2.42 16.2 4.5 13.26

Olive waste

(Hinojosa et al.,

2014)

BBA from burnt 6.84 31.41 2.73 1.39 12.31 2.45 41.49

Olive plant

trimmings

(Sklivaniti et al.,

2017)

BBA from forestry 72.20 17.16 2.32 0.78 0.75 1.97 2.18

Biomass (Modolo

et al., 2015)