Page 26 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 26

allow up to 70%. Reservoirs can be quite complex, with many folds and

several layers of hydrocarbon-bearing rock above each other (in some areas

more than 10). Modern wells are drilled with large horizontal offsets to reach

different parts of the structure and with multiple completions so that one well

can produce from several locations.

3.3 Exploration and drilling

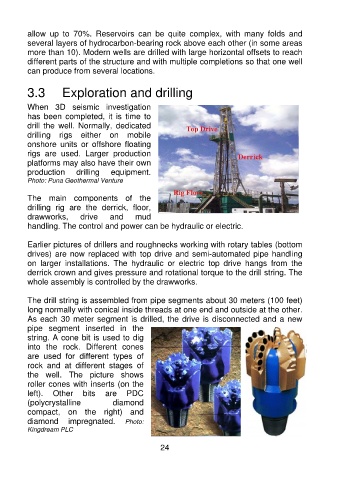

When 3D seismic investigation

has been completed, it is time to

drill the well. Normally, dedicated

drilling rigs either on mobile

onshore units or offshore floating

rigs are used. Larger production

platforms may also have their own

production drilling equipment.

Photo: Puna Geothermal Venture

The main components of the

drilling rig are the derrick, floor,

drawworks, drive and mud

handling. The control and power can be hydraulic or electric.

Earlier pictures of drillers and roughnecks working with rotary tables (bottom

drives) are now replaced with top drive and semi-automated pipe handling

on larger installations. The hydraulic or electric top drive hangs from the

derrick crown and gives pressure and rotational torque to the drill string. The

whole assembly is controlled by the drawworks.

The drill string is assembled from pipe segments about 30 meters (100 feet)

long normally with conical inside threads at one end and outside at the other.

As each 30 meter segment is drilled, the drive is disconnected and a new

pipe segment inserted in the

string. A cone bit is used to dig

into the rock. Different cones

are used for different types of

rock and at different stages of

the well. The picture shows

roller cones with inserts (on the

left). Other bits are PDC

(polycrystalline diamond

compact, on the right) and

diamond impregnated. Photo:

Kingdream PLC

24