Page 42 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 42

4.1 Manifolds and gathering

4.1.1 Pipelines and risers

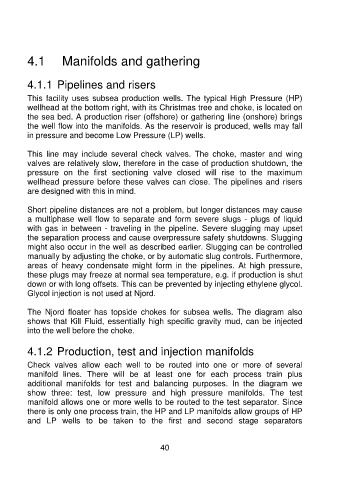

This facility uses subsea production wells. The typical High Pressure (HP)

wellhead at the bottom right, with its Christmas tree and choke, is located on

the sea bed. A production riser (offshore) or gathering line (onshore) brings

the well flow into the manifolds. As the reservoir is produced, wells may fall

in pressure and become Low Pressure (LP) wells.

This line may include several check valves. The choke, master and wing

valves are relatively slow, therefore in the case of production shutdown, the

pressure on the first sectioning valve closed will rise to the maximum

wellhead pressure before these valves can close. The pipelines and risers

are designed with this in mind.

Short pipeline distances are not a problem, but longer distances may cause

a multiphase well flow to separate and form severe slugs - plugs of liquid

with gas in between - traveling in the pipeline. Severe slugging may upset

the separation process and cause overpressure safety shutdowns. Slugging

might also occur in the well as described earlier. Slugging can be controlled

manually by adjusting the choke, or by automatic slug controls. Furthermore,

areas of heavy condensate might form in the pipelines. At high pressure,

these plugs may freeze at normal sea temperature, e.g. if production is shut

down or with long offsets. This can be prevented by injecting ethylene glycol.

Glycol injection is not used at Njord.

The Njord floater has topside chokes for subsea wells. The diagram also

shows that Kill Fluid, essentially high specific gravity mud, can be injected

into the well before the choke.

4.1.2 Production, test and injection manifolds

Check valves allow each well to be routed into one or more of several

manifold lines. There will be at least one for each process train plus

additional manifolds for test and balancing purposes. In the diagram we

show three: test, low pressure and high pressure manifolds. The test

manifold allows one or more wells to be routed to the test separator. Since

there is only one process train, the HP and LP manifolds allow groups of HP

and LP wells to be taken to the first and second stage separators

40