Page 43 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 43

respectively. The chokes are set to reduce the wellhead flow and pressure to

the desired HP and LP pressures respectively.

The desired setting for each well and which of the wells produce at HP and

LP for various production levels are defined by reservoir specialists to

ensure the optimum production and recovery rate.

4.2 Separation

As described earlier, the well-stream may consist of crude oil, gas,

condensates, water and various contaminants. The purpose of the

separators is to split the flow into desirable fractions.

4.2.1 Test separators and well test

Test separators are used to separate the well flow from one or more wells for

analysis and detailed flow measurement. In this way, the behavior of each

well under different pressure flow conditions can be defined. This normally

takes place when the well is taken into production and later at regular

intervals, typically 1-2 months and will measure the total and component flow

rates under different production conditions. Undesirable consequences such

as slugging or sand can also be determined. The separated components are

analyzed in the laboratory to determine hydrocarbon composition of the gas

oil and condensate.

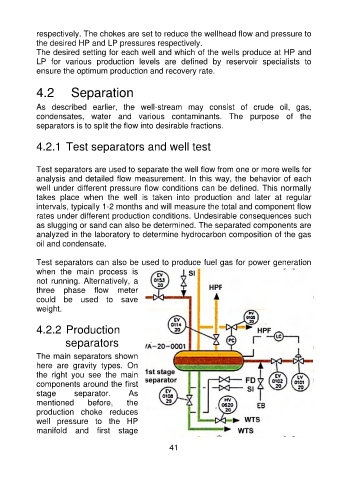

Test separators can also be used to produce fuel gas for power generation

when the main process is

not running. Alternatively, a

three phase flow meter

could be used to save

weight.

4.2.2 Production

separators

The main separators shown

here are gravity types. On

the right you see the main

components around the first

stage separator. As

mentioned before, the

production choke reduces

well pressure to the HP

manifold and first stage

41