Page 44 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 44

separator to about 3-5 MPa (30-50 times atmospheric pressure). Inlet

temperature is often in the range of 100-150 degrees C. On the example

platform, the well stream is colder due to subsea wells and risers.

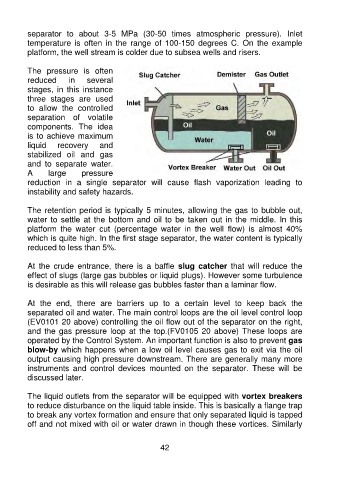

The pressure is often

reduced in several

stages, in this instance

three stages are used

to allow the controlled

separation of volatile

components. The idea

is to achieve maximum

liquid recovery and

stabilized oil and gas

and to separate water.

A large pressure

reduction in a single separator will cause flash vaporization leading to

instability and safety hazards.

The retention period is typically 5 minutes, allowing the gas to bubble out,

water to settle at the bottom and oil to be taken out in the middle. In this

platform the water cut (percentage water in the well flow) is almost 40%

which is quite high. In the first stage separator, the water content is typically

reduced to less than 5%.

At the crude entrance, there is a baffle slug catcher that will reduce the

effect of slugs (large gas bubbles or liquid plugs). However some turbulence

is desirable as this will release gas bubbles faster than a laminar flow.

At the end, there are barriers up to a certain level to keep back the

separated oil and water. The main control loops are the oil level control loop

(EV0101 20 above) controlling the oil flow out of the separator on the right,

and the gas pressure loop at the top.(FV0105 20 above) These loops are

operated by the Control System. An important function is also to prevent gas

blow-by which happens when a low oil level causes gas to exit via the oil

output causing high pressure downstream. There are generally many more

instruments and control devices mounted on the separator. These will be

discussed later.

The liquid outlets from the separator will be equipped with vortex breakers

to reduce disturbance on the liquid table inside. This is basically a flange trap

to break any vortex formation and ensure that only separated liquid is tapped

off and not mixed with oil or water drawn in though these vortices. Similarly

42