Page 49 - Oil and Gas Production Handbook An Introduction to Oil and Gas Production

P. 49

times the volume over the temperature (PV/T) must remain constant. (PV =

nkT). This ends up as a temperature increase.

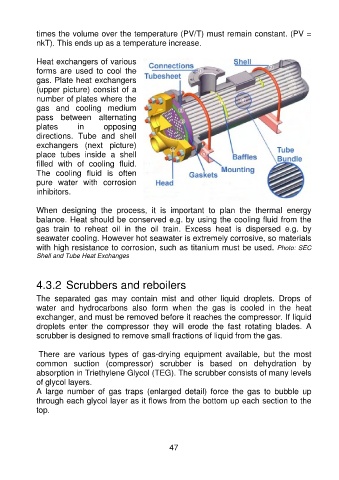

Heat exchangers of various

forms are used to cool the

gas. Plate heat exchangers

(upper picture) consist of a

number of plates where the

gas and cooling medium

pass between alternating

plates in opposing

directions. Tube and shell

exchangers (next picture)

place tubes inside a shell

filled with of cooling fluid.

The cooling fluid is often

pure water with corrosion

inhibitors.

When designing the process, it is important to plan the thermal energy

balance. Heat should be conserved e.g. by using the cooling fluid from the

gas train to reheat oil in the oil train. Excess heat is dispersed e.g. by

seawater cooling. However hot seawater is extremely corrosive, so materials

with high resistance to corrosion, such as titanium must be used. Photo: SEC

Shell and Tube Heat Exchanges

4.3.2 Scrubbers and reboilers

The separated gas may contain mist and other liquid droplets. Drops of

water and hydrocarbons also form when the gas is cooled in the heat

exchanger, and must be removed before it reaches the compressor. If liquid

droplets enter the compressor they will erode the fast rotating blades. A

scrubber is designed to remove small fractions of liquid from the gas.

There are various types of gas-drying equipment available, but the most

common suction (compressor) scrubber is based on dehydration by

absorption in Triethylene Glycol (TEG). The scrubber consists of many levels

of glycol layers.

A large number of gas traps (enlarged detail) force the gas to bubble up

through each glycol layer as it flows from the bottom up each section to the

top.

47