Page 149 - Optical Communications Essentials

P. 149

Connectors and Splices

Connectors and Splices 139

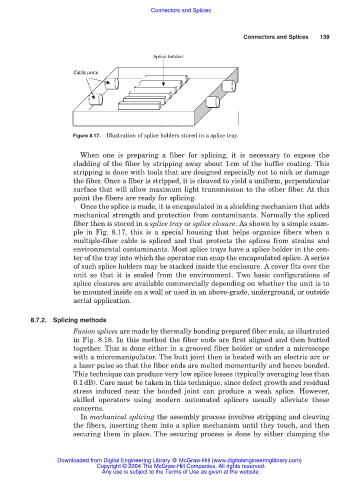

Figure 8.17. Illustration of splice holders stored in a splice tray.

When one is preparing a fiber for splicing, it is necessary to expose the

cladding of the fiber by stripping away about 1cm of the buffer coating. This

stripping is done with tools that are designed especially not to nick or damage

the fiber. Once a fiber is stripped, it is cleaved to yield a uniform, perpendicular

surface that will allow maximum light transmission to the other fiber. At this

point the fibers are ready for splicing.

Once the splice is made, it is encapsulated in a shielding mechanism that adds

mechanical strength and protection from contaminants. Normally the spliced

fiber then is stored in a splice tray or splice closure. As shown by a simple exam-

ple in Fig. 8.17, this is a special housing that helps organize fibers when a

multiple-fiber cable is spliced and that protects the splices from strains and

environmental contaminants. Most splice trays have a splice holder in the cen-

ter of the tray into which the operator can snap the encapsulated splice. A series

of such splice holders may be stacked inside the enclosure. A cover fits over the

unit so that it is sealed from the environment. Two basic configurations of

splice closures are available commercially depending on whether the unit is to

be mounted inside on a wall or used in an above-grade, underground, or outside

aerial application.

8.7.2. Splicing methods

Fusion splices are made by thermally bonding prepared fiber ends, as illustrated

in Fig. 8.18. In this method the fiber ends are first aligned and then butted

together. This is done either in a grooved fiber holder or under a microscope

with a micromanipulator. The butt joint then is heated with an electric arc or

a laser pulse so that the fiber ends are melted momentarily and hence bonded.

This technique can produce very low splice losses (typically averaging less than

0.1 dB). Care must be taken in this technique, since defect growth and residual

stress induced near the bonded joint can produce a weak splice. However,

skilled operators using modern automated splicers usually alleviate these

concerns.

In mechanical splicing the assembly process involves stripping and cleaving

the fibers, inserting them into a splice mechanism until they touch, and then

securing them in place. The securing process is done by either clamping the

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.