Page 150 - Optical Communications Essentials

P. 150

Connectors and Splices

140 Chapter Eight

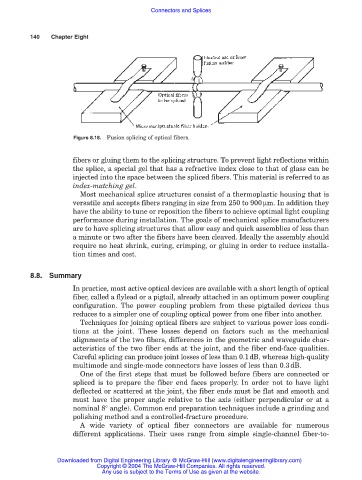

Figure 8.18. Fusion splicing of optical fibers.

fibers or gluing them to the splicing structure. To prevent light reflections within

the splice, a special gel that has a refractive index close to that of glass can be

injected into the space between the spliced fibers. This material is referred to as

index-matching gel.

Most mechanical splice structures consist of a thermoplastic housing that is

versatile and accepts fibers ranging in size from 250 to 900µm. In addition they

have the ability to tune or reposition the fibers to achieve optimal light coupling

performance during installation. The goals of mechanical splice manufacturers

are to have splicing structures that allow easy and quick assemblies of less than

a minute or two after the fibers have been cleaved. Ideally the assembly should

require no heat shrink, curing, crimping, or gluing in order to reduce installa-

tion times and cost.

8.8. Summary

In practice, most active optical devices are available with a short length of optical

fiber, called a flylead or a pigtail, already attached in an optimum power coupling

configuration. The power coupling problem from these pigtailed devices thus

reduces to a simpler one of coupling optical power from one fiber into another.

Techniques for joining optical fibers are subject to various power loss condi-

tions at the joint. These losses depend on factors such as the mechanical

alignments of the two fibers, differences in the geometric and waveguide char-

acteristics of the two fiber ends at the joint, and the fiber end-face qualities.

Careful splicing can produce joint losses of less than 0.1dB, whereas high-quality

multimode and single-mode connectors have losses of less than 0.3dB.

One of the first steps that must be followed before fibers are connected or

spliced is to prepare the fiber end faces properly. In order not to have light

deflected or scattered at the joint, the fiber ends must be flat and smooth and

must have the proper angle relative to the axis (either perpendicular or at a

nominal 8° angle). Common end preparation techniques include a grinding and

polishing method and a controlled-fracture procedure.

A wide variety of optical fiber connectors are available for numerous

different applications. Their uses range from simple single-channel fiber-to-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.