Page 355 - Optical Communications Essentials

P. 355

Manufacturing Issues

Manufacturing Issues 345

moves from one side of the module to the other in proportion to the applied volt-

age. Thus, one module face will be cooled while the other is heated simultan-

eously. As noted in Chap. 6, with appropriate control circuitry TE coolers can

stabilize temperatures to 0.02°C.

In packaging devices such as laser diodes, careful design procedures must be

followed to ensure that the heat generated by the laser chip during operation

will flow away from the laser out of the package. Creating the interface between

a laser chip and the carrier it is mounted on is a standard procedure known as

eutectic die attachment. This bonding traditionally is done by means of a

gold/tin solder (80% Au/ 20% Sn), which can be done in a fairly straightforward

manner in an automated assembly environment.

20.4.3. Mechanical concerns

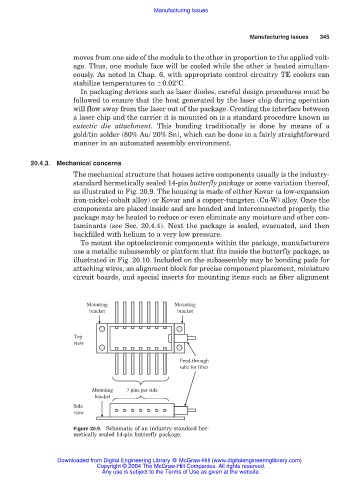

The mechanical structure that houses active components usually is the industry-

standard hermetically sealed 14-pin butterfly package or some variation thereof,

as illustrated in Fig. 20.9. The housing is made of either Kovar (a low-expansion

iron-nickel-cobalt alloy) or Kovar and a copper-tungsten (Cu-W) alloy. Once the

components are placed inside and are bonded and interconnected properly, the

package may be heated to reduce or even eliminate any moisture and other con-

taminants (see Sec. 20.4.4). Next the package is sealed, evacuated, and then

backfilled with helium to a very low pressure.

To mount the optoelectronic components within the package, manufacturers

use a metallic subassembly or platform that fits inside the butterfly package, as

illustrated in Fig. 20.10. Included on the subassembly may be bonding pads for

attaching wires, an alignment block for precise component placement, miniature

circuit boards, and special inserts for mounting items such as fiber alignment

Mounting Mounting

bracket bracket

Top

view

Feed-through

tube for fiber

Mounting 7 pins per side

bracket

Side

view

Figure 20.9. Schematic of an industry-standard her-

metically sealed 14-pin butterfly package.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.