Page 79 - Optical Communications Essentials

P. 79

Optical Fiber Cables

Optical Fiber Cables 69

where long lengths of cable need to be unrolled and retrieved rapidly, LAN links

where fiber cables are placed in cable trays above suspended ceilings, and inter-

building links where cables often need to be pulled through crowded cable ducts.

5.2. Cable Materials and Structures

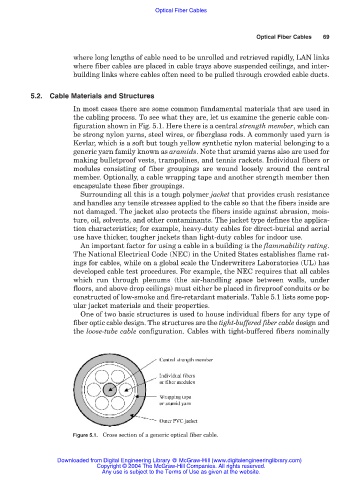

In most cases there are some common fundamental materials that are used in

the cabling process. To see what they are, let us examine the generic cable con-

figuration shown in Fig. 5.1. Here there is a central strength member, which can

be strong nylon yarns, steel wires, or fiberglass rods. A commonly used yarn is

Kevlar, which is a soft but tough yellow synthetic nylon material belonging to a

generic yarn family known as aramids. Note that aramid yarns also are used for

making bulletproof vests, trampolines, and tennis rackets. Individual fibers or

modules consisting of fiber groupings are wound loosely around the central

member. Optionally, a cable wrapping tape and another strength member then

encapsulate these fiber groupings.

Surrounding all this is a tough polymer jacket that provides crush resistance

and handles any tensile stresses applied to the cable so that the fibers inside are

not damaged. The jacket also protects the fibers inside against abrasion, mois-

ture, oil, solvents, and other contaminants. The jacket type defines the applica-

tion characteristics; for example, heavy-duty cables for direct-burial and aerial

use have thicker, tougher jackets than light-duty cables for indoor use.

An important factor for using a cable in a building is the flammability rating.

The National Electrical Code (NEC) in the United States establishes flame rat-

ings for cables, while on a global scale the Underwriters Laboratories (UL) has

developed cable test procedures. For example, the NEC requires that all cables

which run through plenums (the air-handling space between walls, under

floors, and above drop ceilings) must either be placed in fireproof conduits or be

constructed of low-smoke and fire-retardant materials. Table 5.1 lists some pop-

ular jacket materials and their properties.

One of two basic structures is used to house individual fibers for any type of

fiber optic cable design. The structures are the tight-buffered fiber cable design and

the loose-tube cable configuration. Cables with tight-buffered fibers nominally

Figure 5.1. Cross section of a generic optical fiber cable.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.