Page 80 - Optical Communications Essentials

P. 80

Optical Fiber Cables

70 Chapter Five

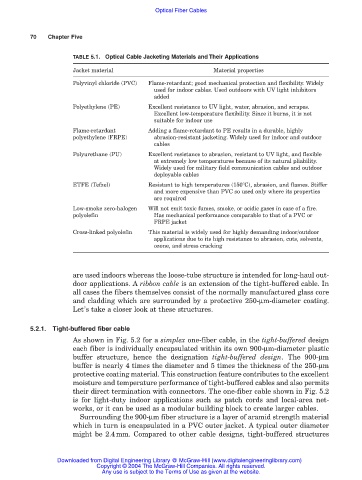

TABLE 5.1. Optical Cable Jacketing Materials and Their Applications

Jacket material Material properties

Polyvinyl chloride (PVC) Flame-retardant; good mechanical protection and flexibility. Widely

used for indoor cables. Used outdoors with UV light inhibitors

added

Polyethylene (PE) Excellent resistance to UV light, water, abrasion, and scrapes.

Excellent low-temperature flexibility. Since it burns, it is not

suitable for indoor use

Flame-retardant Adding a flame-retardant to PE results in a durable, highly

polyethylene (FRPE) abrasion-resistant jacketing. Widely used for indoor and outdoor

cables

Polyurethane (PU) Excellent resistance to abrasion, resistant to UV light, and flexible

at extremely low temperatures because of its natural pliability.

Widely used for military field communication cables and outdoor

deployable cables

ETFE (Tefzel) Resistant to high temperatures (150°C), abrasion, and flames. Stiffer

and more expensive than PVC so used only where its properties

are required

Low-smoke zero-halogen Will not emit toxic fumes, smoke, or acidic gases in case of a fire.

polyolefin Has mechanical performance comparable to that of a PVC or

FRPE jacket

Cross-linked polyolefin This material is widely used for highly demanding indoor/outdoor

applications due to its high resistance to abrasion, cuts, solvents,

ozone, and stress cracking

are used indoors whereas the loose-tube structure is intended for long-haul out-

door applications. A ribbon cable is an extension of the tight-buffered cable. In

all cases the fibers themselves consist of the normally manufactured glass core

and cladding which are surrounded by a protective 250-µm-diameter coating.

Let’s take a closer look at these structures.

5.2.1. Tight-buffered fiber cable

As shown in Fig. 5.2 for a simplex one-fiber cable, in the tight-buffered design

each fiber is individually encapsulated within its own 900-µm-diameter plastic

buffer structure, hence the designation tight-buffered design. The 900-µm

buffer is nearly 4 times the diameter and 5 times the thickness of the 250-µm

protective coating material. This construction feature contributes to the excellent

moisture and temperature performance of tight-buffered cables and also permits

their direct termination with connectors. The one-fiber cable shown in Fig. 5.2

is for light-duty indoor applications such as patch cords and local-area net-

works, or it can be used as a modular building block to create larger cables.

Surrounding the 900-µm fiber structure is a layer of aramid strength material

which in turn is encapsulated in a PVC outer jacket. A typical outer diameter

might be 2.4mm. Compared to other cable designs, tight-buffered structures

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.