Page 165 - Optofluidics Fundamentals, Devices, and Applications

P. 165

140 Cha pte r Se v e n

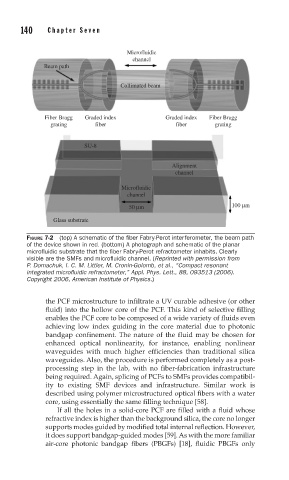

Microfluidic

channel

Beam path

Collimated beam

Fiber Bragg Graded index Graded index Fiber Bragg

grating fiber fiber grating

SU-8

Alignment

channel

Microfluidic

channel

50 μm 100 μm

Glass substrate

FIGURE 7-2 (top) A schematic of the fi ber Fabry-Perot interferometer, the beam path

of the device shown in red. (bottom) A photograph and schematic of the planar

microfl uidic substrate that the fi ber Fabry-Perot refractometer inhabits. Clearly

visible are the SMFs and microfl uidic channel. (Reprinted with permission from

P. Domachuk, I. C. M. Littler, M. Cronin-Golomb, et al., “Compact resonant

integrated microfl uidic refractometer,” Appl. Phys. Lett., 88, 093513 (2006).

Copyright 2006, American Institute of Physics.)

the PCF microstructure to infiltrate a UV curable adhesive (or other

fluid) into the hollow core of the PCF. This kind of selective filling

enables the PCF core to be composed of a wide variety of fluids even

achieving low index guiding in the core material due to photonic

bandgap confinement. The nature of the fluid may be chosen for

enhanced optical nonlinearity, for instance, enabling nonlinear

waveguides with much higher efficiencies than traditional silica

waveguides. Also, the procedure is performed completely as a post-

processing step in the lab, with no fiber-fabrication infrastructure

being required. Again, splicing of PCFs to SMFs provides compatibil-

ity to existing SMF devices and infrastructure. Similar work is

described using polymer microstructured optical fibers with a water

core, using essentially the same filling technique [58].

If all the holes in a solid-core PCF are filled with a fluid whose

refractive index is higher than the background silica, the core no longer

supports modes guided by modified total internal reflection. However,

it does support bandgap-guided modes [59]. As with the more familiar

air-core photonic bandgap fibers (PBGFs) [18], fluidic PBGFs only