Page 166 - Optofluidics Fundamentals, Devices, and Applications

P. 166

Optofluidic Photonic Crystal Fibers: Pr operties and Applications 141

1

II

UV

Cleaving

2

Filling

UV

Cleaving

3

Filling

UV

Filling Cleaving 4

(a)

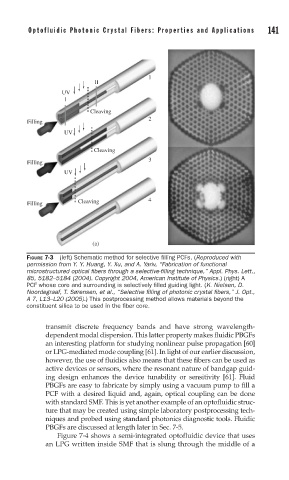

FIGURE 7-3 (left) Schematic method for selective fi lling PCFs. (Reproduced with

permission from Y. Y. Huang, Y. Xu, and A. Yariv, “Fabrication of functional

microstructured optical fi bers through a selective-fi lling technique,” Appl. Phys. Lett.,

85, 5182–5184 (2004). Copyright 2004, American Institute of Physics.) (right) A

PCF whose core and surrounding is selectively fi lled guiding light. (K. Nielsen, D.

Noordegraaf, T. Sørensen, et al., “Selective fi lling of photonic crystal fi bers,” J. Opt.,

A 7, L13–L20 (2005).) This postprocessing method allows materials beyond the

constituent silica to be used in the fi ber core.

transmit discrete frequency bands and have strong wavelength-

dependent modal dispersion. This latter property makes fluidic PBGFs

an interesting platform for studying nonlinear pulse propagation [60]

or LPG-mediated mode coupling [61]. In light of our earlier discussion,

however, the use of fluidics also means that these fibers can be used as

active devices or sensors, where the resonant nature of bandgap guid-

ing design enhances the device tunability or sensitivity [61]. Fluid

PBGFs are easy to fabricate by simply using a vacuum pump to fill a

PCF with a desired liquid and, again, optical coupling can be done

with standard SMF. This is yet another example of an optofluidic struc-

ture that may be created using simple laboratory postprocessing tech-

niques and probed using standard photonics diagnostic tools. Fluidic

PBGFs are discussed at length later in Sec. 7-5.

Figure 7-4 shows a semi-integrated optofluidic device that uses

an LPG written inside SMF that is slung through the middle of a