Page 229 - Optofluidics Fundamentals, Devices, and Applications

P. 229

204 Cha pte r Ni ne

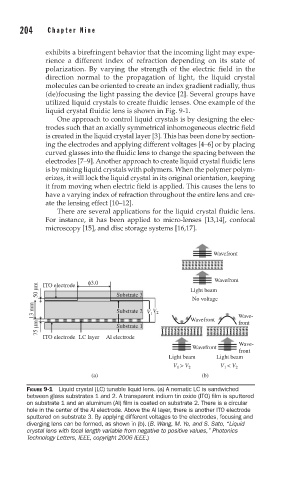

exhibits a birefringent behavior that the incoming light may expe-

rience a different index of refraction depending on its state of

polarization. By varying the strength of the electric field in the

direction normal to the propagation of light, the liquid crystal

molecules can be oriented to create an index gradient radially, thus

(de)focusing the light passing the device [2]. Several groups have

utilized liquid crystals to create fluidic lenses. One example of the

liquid crystal fluidic lens is shown in Fig. 9-1.

One approach to control liquid crystals is by designing the elec-

trodes such that an axially symmetrical inhomogeneous electric field

is created in the liquid crystal layer [3]. This has been done by section-

ing the electrodes and applying different voltages [4–6] or by placing

curved glasses into the fluidic lens to change the spacing between the

electrodes [7–9]. Another approach to create liquid crystal fluidic lens

is by mixing liquid crystals with polymers. When the polymer polym-

erizes, it will lock the liquid crystal in its original orientation, keeping

it from moving when electric field is applied. This causes the lens to

have a varying index of refraction throughout the entire lens and cre-

ate the lensing effect [10–12].

There are several applications for the liquid crystal fluidic lens.

For instance, it has been applied to micro-lenses [13,14], confocal

microscopy [15], and disc storage systems [16,17].

Wavefront

Wavefront

φ3.0

μm ITO electrode Light beam

50 Substrate 3

No voltage

13 mm Substrate 2 V V Wave-

1 2

μm Substrate 1 Wavefront front

75

ITO electrode LC layer Al electrode

Wave-

Wavefront

front

Light beam Light beam

V > V 2 V < V 2

1

1

(a) (b)

FIGURE 9-1 Liquid crystal (LC) tunable liquid lens. (a) A nematic LC is sandwiched

between glass substrates 1 and 2. A transparent indium tin oxide (ITO) fi lm is sputtered

on substrate 1 and an aluminum (Al) fi lm is coated on substrate 2. There is a circular

hole in the center of the Al electrode. Above the Al layer, there is another ITO electrode

sputtered on substrate 3. By applying different voltages to the electrodes, focusing and

diverging lens can be formed, as shown in (b). (B. Wang, M. Ye, and S. Sato, “Liquid

crystal lens with focal length variable from negative to positive values,” Photonics

Technology Letters, IEEE, copyright 2006 IEEE.)