Page 102 - Orlicky's Material Requirements Planning

P. 102

CHAPTER 4 Inventory in a Manufacturing Environment 81

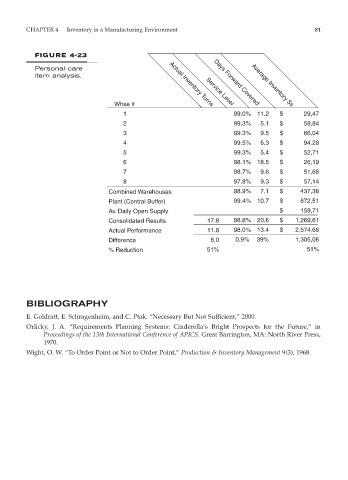

FIGURE 4-23

Personal-care

item analysis. Actual Inventory Turns Days Forward Covered

Whse # Service Level

Average Inventory $s

1 99.0% 11.2 $ 29,47

2 99.3% 5.1 $ 59,84

3 99.3% 9.5 $ 66,04

4 99.5% 6.3 $ 94.28

5 99.3% 5.4 $ 52,71

6 98.1% 18.5 $ 26,19

7 98.7% 9.6 $ 51,68

8 97.8% 9.3 $ 57,14

Combined Warehouses 98.9% 7.1 $ 437,38

Plant (Central Buffer) 99.4% 10.7 $ 672,51

Av. Daily Open Supply $ 159,71

Consolidated Results 17.8 98.8% 20.6 $ 1,269,61

Actual Performance 11.8 98.0% 13.4 $ 2,574,68

Difference 6.0 0.9% 39% 1,305,06

% Reduction 51% 51%

BIBLIOGRAPHY

E. Goldratt, E. Schragenheim, and C. Ptak. “Necessary But Not Sufficient,” 2000.

Orlicky, J. A. “Requirements Planning Systems: Cinderella’s Bright Prospects for the Future,” in

Proceedings of the 13th International Conference of APICS. Great Barrington, MA: North River Press,

1970.

Wight, O. W. “To Order Point or Not to Order Point,” Production & Inventory Management 9(3), 1968.