Page 97 - Orlicky's Material Requirements Planning

P. 97

CHAPTER 4 Inventory in a Manufacturing Environment 77

■ Ensure that the alignment of inventory is better able to cover all points of con-

sumption.

■ Move inventory as few times as possible.

■ Limit plant schedule disruptions that reduce capacity and complicate planning.

■ Remove the plant’s lead time from regional stock level consideration.

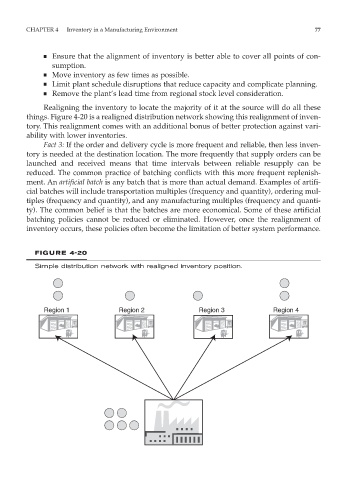

Realigning the inventory to locate the majority of it at the source will do all these

things. Figure 4-20 is a realigned distribution network showing this realignment of inven-

tory. This realignment comes with an additional bonus of better protection against vari-

ability with lower inventories.

Fact 3: If the order and delivery cycle is more frequent and reliable, then less inven-

tory is needed at the destination location. The more frequently that supply orders can be

launched and received means that time intervals between reliable resupply can be

reduced. The common practice of batching conflicts with this more frequent replenish-

ment. An artificial batch is any batch that is more than actual demand. Examples of artifi-

cial batches will include transportation multiples (frequency and quantity), ordering mul-

tiples (frequency and quantity), and any manufacturing multiples (frequency and quanti-

ty). The common belief is that the batches are more economical. Some of these artificial

batching policies cannot be reduced or eliminated. However, once the realignment of

inventory occurs, these policies often become the limitation of better system performance.

FIGURE 4-20

Simple distribution network with realigned inventory position.

Region 1 Region 2 Region 3 Region 4