Page 94 - Orlicky's Material Requirements Planning

P. 94

74 PART 2 Concepts

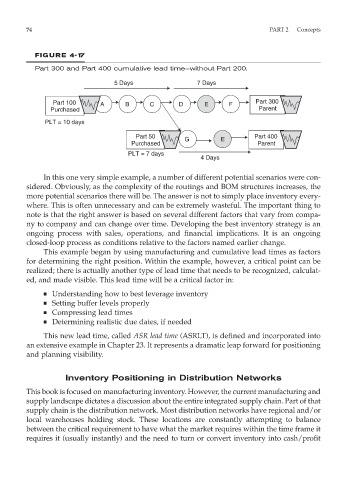

FIGURE 4-17

Part 300 and Part 400 cumulative lead time—without Part 200.

5 Days 7 Days

Part 100 A B C D E F Part 300

Purchased Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days

In this one very simple example, a number of different potential scenarios were con-

sidered. Obviously, as the complexity of the routings and BOM structures increases, the

more potential scenarios there will be. The answer is not to simply place inventory every-

where. This is often unnecessary and can be extremely wasteful. The important thing to

note is that the right answer is based on several different factors that vary from compa-

ny to company and can change over time. Developing the best inventory strategy is an

ongoing process with sales, operations, and financial implications. It is an ongoing

closed-loop process as conditions relative to the factors named earlier change.

This example began by using manufacturing and cumulative lead times as factors

for determining the right position. Within the example, however, a critical point can be

realized; there is actually another type of lead time that needs to be recognized, calculat-

ed, and made visible. This lead time will be a critical factor in:

■ Understanding how to best leverage inventory

■ Setting buffer levels properly

■ Compressing lead times

■ Determining realistic due dates, if needed

This new lead time, called ASR lead time (ASRLT), is defined and incorporated into

an extensive example in Chapter 23. It represents a dramatic leap forward for positioning

and planning visibility.

Inventory Positioning in Distribution Networks

This book is focused on manufacturing inventory. However, the current manufacturing and

supply landscape dictates a discussion about the entire integrated supply chain. Part of that

supply chain is the distribution network. Most distribution networks have regional and/or

local warehouses holding stock. These locations are constantly attempting to balance

between the critical requirement to have what the market requires within the time frame it

requires it (usually instantly) and the need to turn or convert inventory into cash/profit