Page 90 - Orlicky's Material Requirements Planning

P. 90

70 PART 2 Concepts

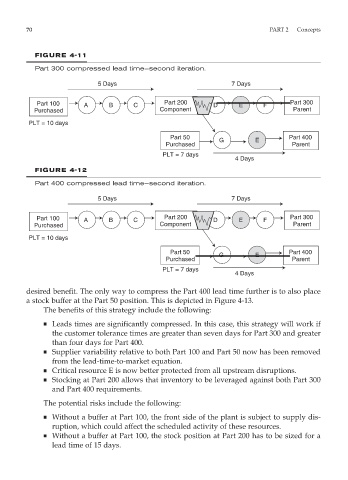

FIGURE 4-11

Part 300 compressed lead time—second iteration.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days

FIGURE 4-12

Part 400 compressed lead time—second iteration.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days

desired benefit. The only way to compress the Part 400 lead time further is to also place

a stock buffer at the Part 50 position. This is depicted in Figure 4-13.

The benefits of this strategy include the following:

■ Leads times are significantly compressed. In this case, this strategy will work if

the customer tolerance times are greater than seven days for Part 300 and greater

than four days for Part 400.

■ Supplier variability relative to both Part 100 and Part 50 now has been removed

from the lead-time-to-market equation.

■ Critical resource E is now better protected from all upstream disruptions.

■ Stocking at Part 200 allows that inventory to be leveraged against both Part 300

and Part 400 requirements.

The potential risks include the following:

■ Without a buffer at Part 100, the front side of the plant is subject to supply dis-

ruption, which could affect the scheduled activity of these resources.

■ Without a buffer at Part 100, the stock position at Part 200 has to be sized for a

lead time of 15 days.