Page 86 - Orlicky's Material Requirements Planning

P. 86

66 PART 2 Concepts

cumulative lead time (CLT): The longest planned length of time to accomplish the

activity in question. It is found by reviewing the lead time for each bill of material path

below the item; whichever path adds up to the greatest number defines cumulative

lead time.

purchasing lead time (PLT): The total lead time required to obtain a purchased item.

Included here are order preparation and release time; supplier lead time; transporta-

tion time; and receiving, inspection, and put away time. 3

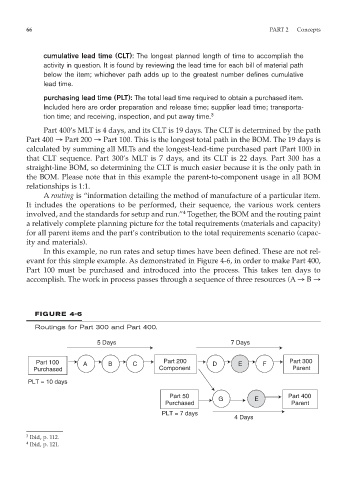

Part 400’s MLT is 4 days, and its CLT is 19 days. The CLT is determined by the path

Part 400 → Part 200 → Part 100. This is the longest total path in the BOM. The 19 days is

calculated by summing all MLTs and the longest-lead-time purchased part (Part 100) in

that CLT sequence. Part 300’s MLT is 7 days, and its CLT is 22 days. Part 300 has a

straight-line BOM, so determining the CLT is much easier because it is the only path in

the BOM. Please note that in this example the parent-to-component usage in all BOM

relationships is 1:1.

A routing is “information detailing the method of manufacture of a particular item.

It includes the operations to be performed, their sequence, the various work centers

4

involved, and the standards for setup and run.” Together, the BOM and the routing paint

a relatively complete planning picture for the total requirements (materials and capacity)

for all parent items and the part’s contribution to the total requirements scenario (capac-

ity and materials).

In this example, no run rates and setup times have been defined. These are not rel-

evant for this simple example. As demonstrated in Figure 4-6, in order to make Part 400,

Part 100 must be purchased and introduced into the process. This takes ten days to

accomplish. The work in process passes through a sequence of three resources (A → B →

FIGURE 4-6

Routings for Part 300 and Part 400.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days

3 Ibid, p. 112.

4 Ibid, p. 121.