Page 91 - Orlicky's Material Requirements Planning

P. 91

CHAPTER 4 Inventory in a Manufacturing Environment 71

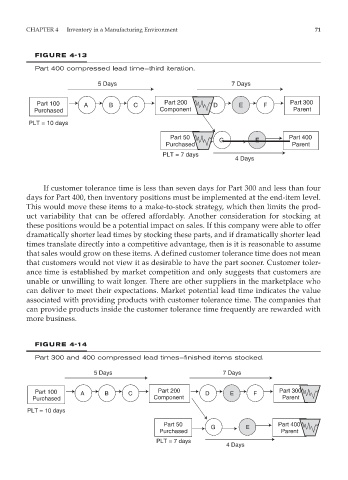

FIGURE 4-13

Part 400 compressed lead time—third iteration.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days

If customer tolerance time is less than seven days for Part 300 and less than four

days for Part 400, then inventory positions must be implemented at the end-item level.

This would move these items to a make-to-stock strategy, which then limits the prod-

uct variability that can be offered affordably. Another consideration for stocking at

these positions would be a potential impact on sales. If this company were able to offer

dramatically shorter lead times by stocking these parts, and if dramatically shorter lead

times translate directly into a competitive advantage, then is it is reasonable to assume

that sales would grow on these items. A defined customer tolerance time does not mean

that customers would not view it as desirable to have the part sooner. Customer toler-

ance time is established by market competition and only suggests that customers are

unable or unwilling to wait longer. There are other suppliers in the marketplace who

can deliver to meet their expectations. Market potential lead time indicates the value

associated with providing products with customer tolerance time. The companies that

can provide products inside the customer tolerance time frequently are rewarded with

more business.

FIGURE 4-14

Part 300 and 400 compressed lead times—finished items stocked.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days