Page 92 - Orlicky's Material Requirements Planning

P. 92

72 PART 2 Concepts

The benefits to this inventory strategy include the following:

■ Leads times are fully compressed. In this simple case, this inventory strategy will

work if the customer tolerance times are one or more days for Part 300 and one

or more days for Part 400.

■ Potential sales gains are possible for the sales of both Part 300 and Part 400 if the

market will reward this company for shorter than industry standard lead times.

The potential risks include the following:

■ Stocking only at the end-item level means that the level of stock needs to cover

the entire cumulative lead times of both products (22 and 19 days).

■ Stocking only at the end-item level leaves critical resource E exposed to both

internal and external disruptions.

■ The resources required to have inventory at the end-item level would necessitate

lower variety offered to the market.

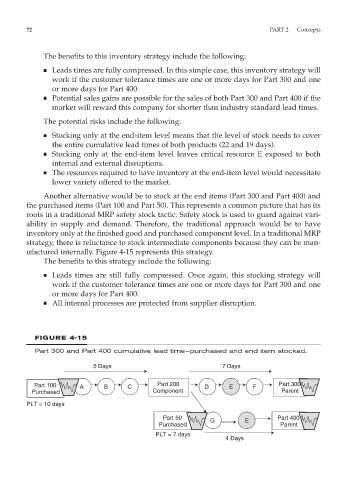

Another alternative would be to stock at the end items (Part 300 and Part 400) and

the purchased items (Part 100 and Part 50). This represents a common picture that has its

roots in a traditional MRP safety stock tactic. Safety stock is used to guard against vari-

ability in supply and demand. Therefore, the traditional approach would be to have

inventory only at the finished good and purchased component level. In a traditional MRP

strategy, there is reluctance to stock intermediate components because they can be man-

ufactured internally. Figure 4-15 represents this strategy.

The benefits to this strategy include the following:

■ Leads times are still fully compressed. Once again, this stocking strategy will

work if the customer tolerance times are one or more days for Part 300 and one

or more days for Part 400.

■ All internal processes are protected from supplier disruption.

FIGURE 4-15

Part 300 and Part 400 cumulative lead time—purchased and end item stocked.

5 Days 7 Days

Part 100 A B C Part 200 D E F Part 300

Purchased Component Parent

PLT = 10 days

Part 50 G E Part 400

Purchased Parent

PLT = 7 days

4 Days