Page 225 - Orlicky's Material Requirements Planning

P. 225

204 PART 3 Managing with the MRP System

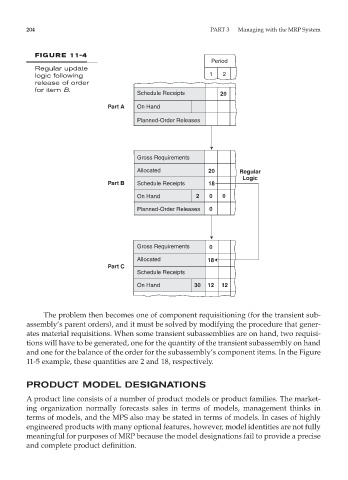

FIGURE 11-4

Period

Regular update

logic following 1 2

release of order

for item B.

Schedule Receipts 20

Part A On Hand

Planned-Order Releases

Gross Requirements

Allocated 20 Regular

Logic

Part B Schedule Receipts 18

On Hand 2 0 0

Planned-Order Releases 0

Gross Requirements 0

Allocated 18

Part C

Schedule Receipts

On Hand 30 12 12

The problem then becomes one of component requisitioning (for the transient sub-

assembly’s parent orders), and it must be solved by modifying the procedure that gener-

ates material requisitions. When some transient subassemblies are on hand, two requisi-

tions will have to be generated, one for the quantity of the transient subassembly on hand

and one for the balance of the order for the subassembly’s component items. In the Figure

11-5 example, these quantities are 2 and 18, respectively.

PRODUCT MODEL DESIGNATIONS

A product line consists of a number of product models or product families. The market-

ing organization normally forecasts sales in terms of models, management thinks in

terms of models, and the MPS also may be stated in terms of models. In cases of highly

engineered products with many optional features, however, model identities are not fully

meaningful for purposes of MRP because the model designations fail to provide a precise

and complete product definition.