Page 482 - Orlicky's Material Requirements Planning

P. 482

CHAPTER 27 Highly Visible and Collaborative Execution 459

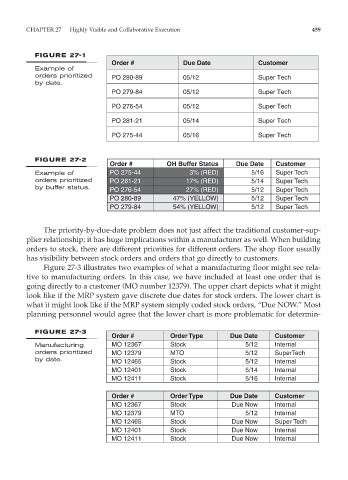

FIGURE 27-1

Order # Due Date Customer

Example of

orders prioritized PO 280-89 05/12 Super Tech

by date.

PO 279-84 05/12 Super Tech

PO 276-54 05/12 Super Tech

PO 281-21 05/14 Super Tech

PO 275-44 05/16 Super Tech

FIGURE 27-2

Order # OH Buffer Status Due Date Customer

Example of PO 275-44 3% (RED) 5/16 Super Tech

orders prioritized PO 281-21 17% (RED) 5/14 Super Tech

by buffer status.

PO 276-54 27% (RED) 5/12 Super Tech

PO 280-89 47% (YELLOW) 5/12 Super Tech

PO 279-84 54% (YELLOW) 5/12 Super Tech

The priority-by-due-date problem does not just affect the traditional customer-sup-

plier relationship; it has huge implications within a manufacturer as well. When building

orders to stock, there are different priorities for different orders. The shop floor usually

has visibility between stock orders and orders that go directly to customers.

Figure 27-3 illustrates two examples of what a manufacturing floor might see rela-

tive to manufacturing orders. In this case, we have included at least one order that is

going directly to a customer (MO number 12379). The upper chart depicts what it might

look like if the MRP system gave discrete due dates for stock orders. The lower chart is

what it might look like if the MRP system simply coded stock orders, “Due NOW.” Most

planning personnel would agree that the lower chart is more problematic for determin-

FIGURE 27-3

Order # Order Type Due Date Customer

Manufacturing MO 12367 Stock 5/12 Internal

orders prioritized MO 12379 MTO 5/12 SuperTech

by date. MO 12465 Stock 5/12 Internal

MO 12401 Stock 5/14 Internal

MO 12411 Stock 5/16 Internal

Order # Order Type Due Date Customer

MO 12367 Stock Due Now Internal

MO 12379 MTO 5/12 Internal

MO 12465 Stock Due Now Super Tech

MO 12401 Stock Due Now Internal

MO 12411 Stock Due Now Internal