Page 484 - Orlicky's Material Requirements Planning

P. 484

CHAPTER 27 Highly Visible and Collaborative Execution 461

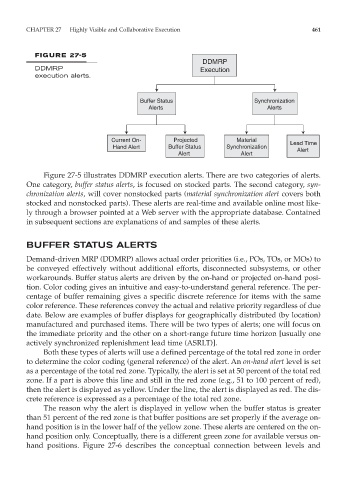

FIGURE 27-5

DDMRP

DDMRP Execution

execution alerts.

Buffer Status Synchronization

Alerts Alerts

Current On- Projected Material Lead Time

Hand Alert Buffer Status Synchronization Alert

Alert Alert

Figure 27-5 illustrates DDMRP execution alerts. There are two categories of alerts.

One category, buffer status alerts, is focused on stocked parts. The second category, syn-

chronization alerts, will cover nonstocked parts (material synchronization alert covers both

stocked and nonstocked parts). These alerts are real-time and available online most like-

ly through a browser pointed at a Web server with the appropriate database. Contained

in subsequent sections are explanations of and samples of these alerts.

BUFFER STATUS ALERTS

Demand-driven MRP (DDMRP) allows actual order priorities (i.e., POs, TOs, or MOs) to

be conveyed effectively without additional efforts, disconnected subsystems, or other

workarounds. Buffer status alerts are driven by the on-hand or projected on-hand posi-

tion. Color coding gives an intuitive and easy-to-understand general reference. The per-

centage of buffer remaining gives a specific discrete reference for items with the same

color reference. These references convey the actual and relative priority regardless of due

date. Below are examples of buffer displays for geographically distributed (by location)

manufactured and purchased items. There will be two types of alerts; one will focus on

the immediate priority and the other on a short-range future time horizon [usually one

actively synchronized replenishment lead time (ASRLT)].

Both these types of alerts will use a defined percentage of the total red zone in order

to determine the color coding (general reference) of the alert. An on-hand alert level is set

as a percentage of the total red zone. Typically, the alert is set at 50 percent of the total red

zone. If a part is above this line and still in the red zone (e.g., 51 to 100 percent of red),

then the alert is displayed as yellow. Under the line, the alert is displayed as red. The dis-

crete reference is expressed as a percentage of the total red zone.

The reason why the alert is displayed in yellow when the buffer status is greater

than 51 percent of the red zone is that buffer positions are set properly if the average on-

hand position is in the lower half of the yellow zone. These alerts are centered on the on-

hand position only. Conceptually, there is a different green zone for available versus on-

hand positions. Figure 27-6 describes the conceptual connection between levels and