Page 119 -

P. 119

106 Chapter Eight

1

3 / 2 in

1

1

4 / 2 in 4 / 2 in

32 in

3

3

4 / 4 in 4 / 4 in

1

9 / 2 in

1

1

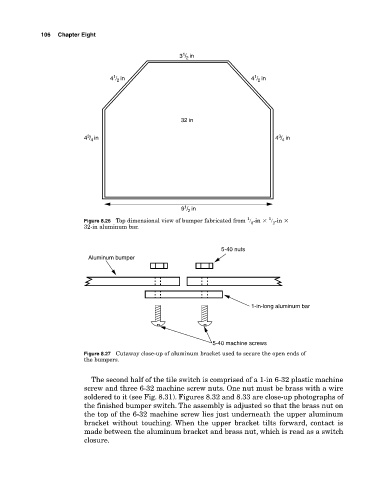

Figure 8.26 Top dimensional view of bumper fabricated from � in � � in �

8

2

32in aluminum bar.

5-40 nuts

Aluminum bumper

1-in-long aluminum bar

5-40 machine screws

Figure 8.27 Cutaway closeup of aluminum bracket used to secure the open ends of

the bumpers.

The second half of the tile switch is comprised of a 1in 632 plastic machine

screw and three 632 machine screw nuts. One nut must be brass with a wire

soldered to it (see Fig. 8.31). Figures 8.32 and 8.33 are closeup photographs of

the finished bumper switch. The assembly is adjusted so that the brass nut on

the top of the 632 machine screw lies just underneath the upper aluminum

bracket without touching. When the upper bracket tilts forward, contact is

made between the aluminum bracket and brass nut, which is read as a switch

closure.