Page 174 - Petroleum and Gas Field Processing

P. 174

in the settling section to speed up the buildup and the formation of water

drops, (2) applying centrifugal force to the emulsion that can promote

separation, and (3) applying an electrical field in the settling section of the

treater.

The principle of breaking oil–water emulsions using electrical current

is known as electrostatic separation. Ionization of these emulsions with the

aid of electric field was introduced in 1930 for crude oil desalting in

oil refineries. High-voltage field (10,000 to 15,000 v) is used to help

dehydration according to the following steps:

1. The water droplet is made up of polar molecules, because the

oxygen atom has a negative end, and the hydrogen atoms have

positive charges. These polar forces are magnetized and respond

to an external electrical force field. Therefore, a dipole

attraction between the water droplets in the emulsion is

established, leading to coalescence, hence settling and separation

(see Fig. 17).

2. As a result of the high-voltage field, the water droplets vibrate

rapidly, causing the stabilizing film to weaken and break.

3. The surface of the water droplets expand (their shapes change

into ellipsoids); thus attracted to each other, they collide and

then coalesce, as depicted in Figure 18.

4. As the water droplets combine, they grow in size until they

become heavy enough to separate by settling to the bottom of

the treater.

5.7 CHEMIELECTRIC DEHYDRATROS

(EMULSION TREATERS)

It is normal practice to call emulsion treaters ‘‘heater treaters.’’ However,

when other or additional treating aids are used, the name of the treater

would be made to reflect such aids of treatment. Consequently, a name

such as chemielectric dehydrator is used to indicate that both chemical and

electrical aids are used (in addition to heating) in the treatment.

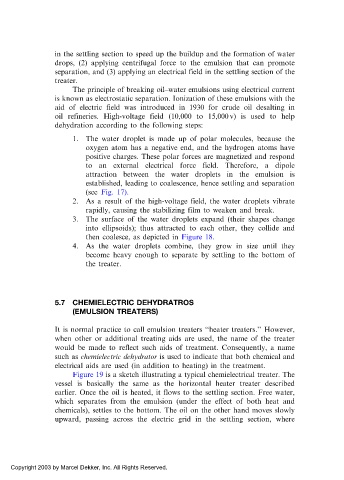

Figure 19 is a sketch illustrating a typical chemielectrical treater. The

vessel is basically the same as the horizontal heater treater described

earlier. Once the oil is heated, it flows to the settling section. Free water,

which separates from the emulsion (under the effect of both heat and

chemicals), settles to the bottom. The oil on the other hand moves slowly

upward, passing across the electric grid in the settling section, where

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.