Page 172 - Petroleum and Gas Field Processing

P. 172

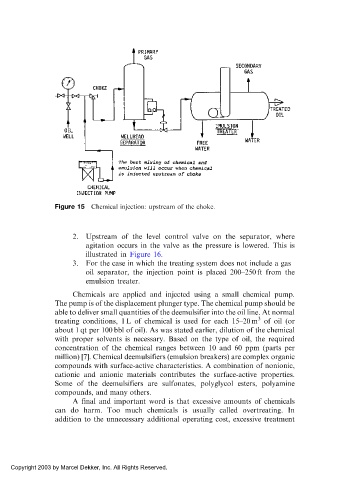

Figure 15 Chemical injection: upstream of the choke.

2. Upstream of the level control valve on the separator, where

agitation occurs in the valve as the pressure is lowered. This is

illustrated in Figure 16.

3. For the case in which the treating system does not include a gas–

oil separator, the injection point is placed 200–250 ft from the

emulsion treater.

Chemicals are applied and injected using a small chemical pump.

The pump is of the displacement plunger type. The chemical pump should be

able to deliver small quantities of the deemulsifier into the oil line. At normal

3

treating conditions, 1 L of chemical is used for each 15–20 m of oil (or

about 1 qt per 100 bbl of oil). As was stated earlier, dilution of the chemical

with proper solvents is necessary. Based on the type of oil, the required

concentration of the chemical ranges between 10 and 60 ppm (parts per

million) [7]. Chemical deemulsifiers (emulsion breakers) are complex organic

compounds with surface-active characteristics. A combination of nonionic,

cationic and anionic materials contributes the surface-active properties.

Some of the deemulsifiers are sulfonates, polyglycol esters, polyamine

compounds, and many others.

A final and important word is that excessive amounts of chemicals

can do harm. Too much chemicals is usually called overtreating. In

addition to the unnecessary additional operating cost, excessive treatment

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.