Page 171 - Petroleum and Gas Field Processing

P. 171

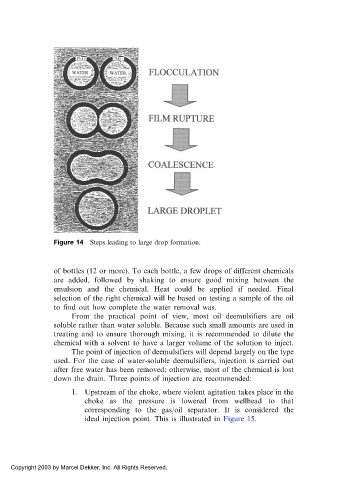

Figure 14 Steps leading to large drop formation.

of bottles (12 or more). To each bottle, a few drops of different chemicals

are added, followed by shaking to ensure good mixing between the

emulsion and the chemical. Heat could be applied if needed. Final

selection of the right chemical will be based on testing a sample of the oil

to find out how complete the water removal was.

From the practical point of view, most oil deemulsifiers are oil

soluble rather than water soluble. Because such small amounts are used in

treating and to ensure thorough mixing, it is recommended to dilute the

chemical with a solvent to have a larger volume of the solution to inject.

The point of injection of deemulsifiers will depend largely on the type

used. For the case of water-soluble deemulsifiers, injection is carried out

after free water has been removed; otherwise, most of the chemical is lost

down the drain. Three points of injection are recommended:

1. Upstream of the choke, where violent agitation takes place in the

choke as the pressure is lowered from wellhead to that

corresponding to the gas/oil separator. It is considered the

ideal injection point. This is illustrated in Figure 15.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.