Page 238 - Petroleum and Gas Field Processing

P. 238

are used when water treatment is performed under pressures above the

atmospheric pressure. These equipment are normally large in volume to

provide residence time that is sufficiently long (10–30 min) for the

coalescence and gravity separation of the oil droplets.

Pressure vessels are more expensive than atmospheric tanks.

However, the choice is controlled by the overall requirements of the

water treatment system. Pressure vessels are normally preferred over

atmospheric tanks for the following reasons:

1. To avoid the potential gas venting problems associated with

atmospheric tanks

2. To eliminate the potential danger of overpressure that may occur

in an atmospheric tank

3. To eliminate the need for pumps that may be required to deliver

the treated water to other secondary treating equipment or to

other locations for disposal

The technical aspects, benefits, and cost should all be considered in

deciding on the pressure rating of the skimmers.

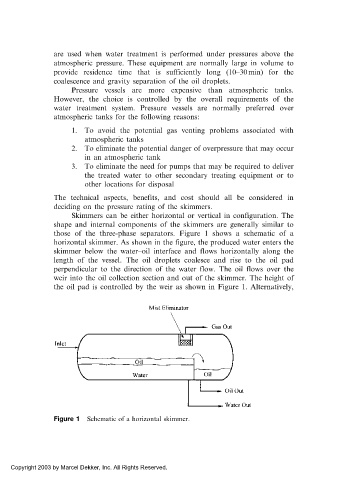

Skimmers can be either horizontal or vertical in configuration. The

shape and internal components of the skimmers are generally similar to

those of the three-phase separators. Figure 1 shows a schematic of a

horizontal skimmer. As shown in the figure, the produced water enters the

skimmer below the water–oil interface and flows horizontally along the

length of the vessel. The oil droplets coalesce and rise to the oil pad

perpendicular to the direction of the water flow. The oil flows over the

weir into the oil collection section and out of the skimmer. The height of

the oil pad is controlled by the weir as shown in Figure 1. Alternatively,

Figure 1 Schematic of a horizontal skimmer.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.