Page 318 - Petroleum and Gas Field Processing

P. 318

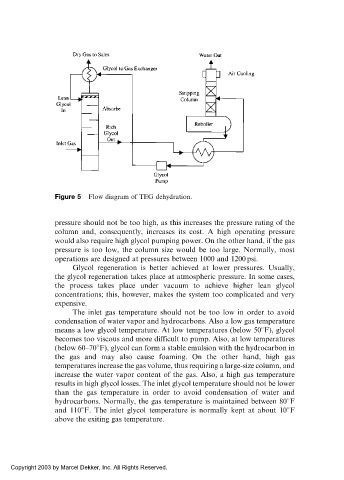

Figure 5 Flow diagram of TEG dehydration.

pressure should not be too high, as this increases the pressure rating of the

column and, consequently, increases its cost. A high operating pressure

would also require high glycol pumping power. On the other hand, if the gas

pressure is too low, the column size would be too large. Normally, most

operations are designed at pressures between 1000 and 1200 psi.

Glycol regeneration is better achieved at lower pressures. Usually,

the glycol regeneration takes place at atmospheric pressure. In some cases,

the process takes place under vacuum to achieve higher lean glycol

concentrations; this, however, makes the system too complicated and very

expensive.

The inlet gas temperature should not be too low in order to avoid

condensation of water vapor and hydrocarbons. Also a low gas temperature

means a low glycol temperature. At low temperatures (below 50 F), glycol

becomes too viscous and more difficult to pump. Also, at low temperatures

(below 60–70 F), glycol can form a stable emulsion with the hydrocarbon in

the gas and may also cause foaming. On the other hand, high gas

temperatures increase the gas volume, thus requiring a large-size column, and

increase the water vapor content of the gas. Also, a high gas temperature

results in high glycol losses. The inlet glycol temperature should not be lower

than the gas temperature in order to avoid condensation of water and

hydrocarbons. Normally, the gas temperature is maintained between 80 F

and 110 F. The inlet glycol temperature is normally kept at about 10 F

above the exiting gas temperature.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.