Page 358 - Petrophysics 2E

P. 358

326 PETROPHYSICS: RESERVOIR ROCK PROPERTIES

that play a decisive role in the behavior of the capillary pressure curves.

Therefore, when mercury injection data are normalized to represent

water-oil systems, the state of wettability must be considered.

The mercury injection method has two disadvantages:

(1) after mercury is injected into a core, it cannot be used for any other

tests because the mercury cannot be safely removed, and

(2) mercury vapor is toxic, so strict safety precautions must be followed

when using mercury.

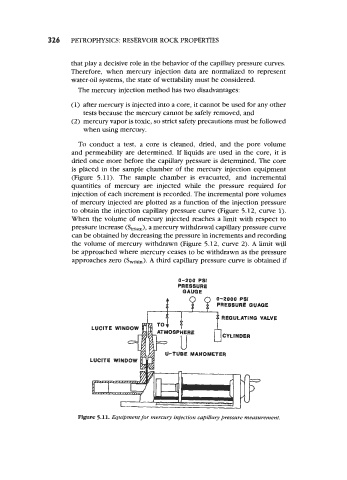

To conduct a test, a core is cleaned, dried, and the pore volume

and permeability are determined. If liquids are used in the core, it is

dried once more before the capillary pressure is determined. The core

is placed in the sample chamber of the mercury injection equipment

(Figure 5.11). The sample chamber is evacuated, and incremental

quantities of mercury are injected while the pressure required for

injection of each increment is recorded. The incremental pore volumes

of mercury injected are plotted as a function of the injection pressure

to obtain the injection capillary pressure curve (Figure 5.12, curve 1).

When the volume of mercury injected reaches a limit with respect to

pressure increase (S-), a mercury withdrawal capillary pressure curve

can be obtained by decreasing the pressure in increments and recording

the volume of mercury withdrawn (Figure 5.12, curve 2). A limit will

be approached where mercury ceases to be withdrawn as the pressure

approaches zero (Swmh>. A third capillary pressure curve is obtained if

0-200 PSI

PRESSURE

GAUQE

0-2000 PSI

PRESSURE WAGE

REGULATING VALVE

LUCITE WINDOW

LUClTE WINDOW

Figure 5.11. Equdpment for mercury Injection Capillary pressure measurement.