Page 207 - Photodetection and Measurement - Maximizing Performance in Optical Systems

P. 207

Contamination and Industrial Systems

200 Chapter Nine

materials for these, which are now available with very high quality optical

surfaces at low cost. Their wavelength of operation is limited at short wavelength

to approximately 350nm, but for many laboratory, treatment works, and indus-

trial manual testing applications using spectroscopy, turbidity, and indicator

chemicals, this is sufficient. Although they are often used for repeated measure-

ments, the plastic’s easily damaged optical surfaces make this a risky endeavour

compared with glass or silica cuvettes. In any case, the cost of these measure-

ments is usually dominated by the cost of getting to the site, obtaining a sample,

performing the measurement and thinking about the results, so that disposable

measurement cells contribute only negligible cost in many applications.

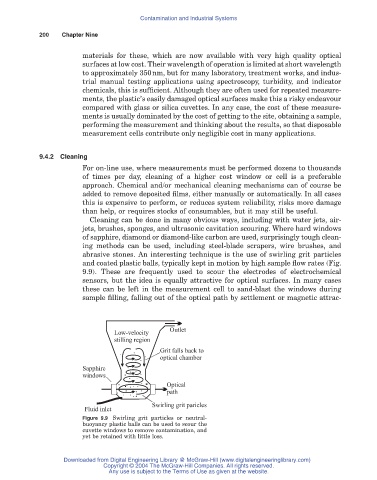

9.4.2 Cleaning

For on-line use, where measurements must be performed dozens to thousands

of times per day, cleaning of a higher cost window or cell is a preferable

approach. Chemical and/or mechanical cleaning mechanisms can of course be

added to remove deposited films, either manually or automatically. In all cases

this is expensive to perform, or reduces system reliability, risks more damage

than help, or requires stocks of consumables, but it may still be useful.

Cleaning can be done in many obvious ways, including with water jets, air-

jets, brushes, sponges, and ultrasonic cavitation scouring. Where hard windows

of sapphire, diamond or diamond-like carbon are used, surprisingly tough clean-

ing methods can be used, including steel-blade scrapers, wire brushes, and

abrasive stones. An interesting technique is the use of swirling grit particles

and coated plastic balls, typically kept in motion by high sample flow rates (Fig.

9.9). These are frequently used to scour the electrodes of electrochemical

sensors, but the idea is equally attractive for optical surfaces. In many cases

these can be left in the measurement cell to sand-blast the windows during

sample filling, falling out of the optical path by settlement or magnetic attrac-

Outlet

Low-velocity

stilling region

Grit falls back to

optical chamber

Sapphire

windows

Optical

path

Swirling grit paricles

Fluid inlet

Figure 9.9 Swirling grit particles or neutral-

buoyancy plastic balls can be used to scour the

cuvette windows to remove contamination, and

yet be retained with little loss.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.