Page 227 - Pipeline Pigging Technology

P. 227

Pipeline Pigging Technology

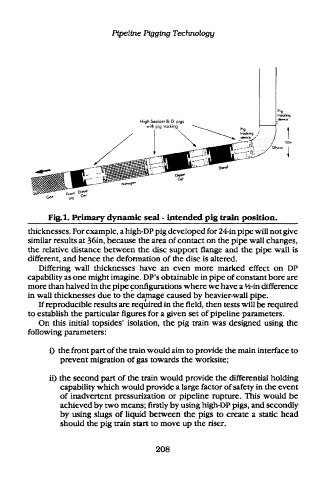

Fig.l. Primary dynamic seal - intended pig train position.

thicknesses. For example, a high-DP pig developed for 24-in pipe will not give

similar results at 36in, because the area of contact on the pipe wall changes,

the relative distance between the disc support flange and the pipe wall is

different, and hence the deformation of the disc is altered.

Differing wall thicknesses have an even more marked effect on DP

capability as one might imagine. DP's obtainable in pipe of constant bore are

more than halved in the pipe configurations where we have a ^-in difference

in wall thicknesses due to the damage caused by heavier-wall pipe.

If reproducible results are required in the field, then tests will be required

to establish the particular figures for a given set of pipeline parameters.

On this initial topsides' isolation, the pig train was designed using the

following parameters:

i) the front part of the train would aim to provide the main interface to

prevent migration of gas towards the worksite;

ii) the second part of the train would provide the differential holding

capability which would provide a large factor of safety in the event

of inadvertent pressurization or pipeline rupture. This would be

achieved by two means; firstly by using high-DP pigs, and secondly

by using slugs of liquid between the pigs to create a static head

should the pig train start to move up the riser.

208