Page 286 - Pipeline Pigging Technology

P. 286

Pigging for pipeline integrity analysis

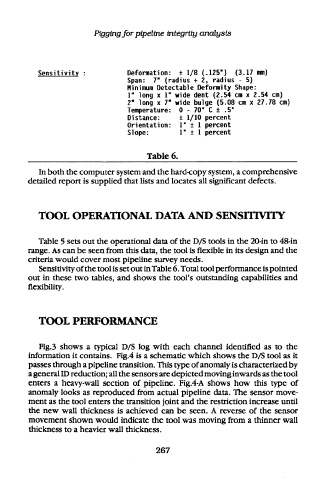

Sensitivity : Deformation: ± 1/8 (.125") (3.17 mm)

Span: 7" (radius + 2, radius - 5)

Minimum Detectable Deformity Shape:

1" long x 1" wide dent (2.54 cm x 2.54 cm)

2" long x 7" wide bulge (5.08 cm x 27.78 cm)

Temperature: 0 - 70* C ± .5"

Distance: ± 1/10 percent

Orientation: 1* ± 1 percent

Slope: 1* ± 1 percent

Table 6.

In both the computer system and the hard-copy system, a comprehensive

detailed report is supplied that lists and locates all significant defects.

TOOL OPERATIONAL DATA AND SENSITIVITY

Table 5 sets out the operational data of the D/S tools in the 20-in to 48-in

range. As can be seen from this data, the tool is flexible in its design and the

criteria would cover most pipeline survey needs.

Sensitivity of the tool is set out in Table 6. Total tool performance is pointed

out in these two tables, and shows the tool's outstanding capabilities and

flexibility.

TOOL PERFORMANCE

Fig. 3 shows a typical D/S log with each channel identified as to the

information it contains. Fig.4 is a schematic which shows the D/S tool as it

passes through a pipeline transition. This type of anomaly is characterized by

a general ID reduction; all the sensors are depicted moving inwards as the tool

enters a heavy-wall section of pipeline. Fig.4-A shows how this type of

anomaly looks as reproduced from actual pipeline data. The sensor move-

ment as the tool enters the transition joint and the restriction increase until

the new wall thickness is achieved can be seen. A reverse of the sensor

movement shown would indicate the tool was moving from a thinner wall

thickness to a heavier wall thickness.

267