Page 282 - Pipeline Pigging Technology

P. 282

Pigging for pipeline integritit analysis

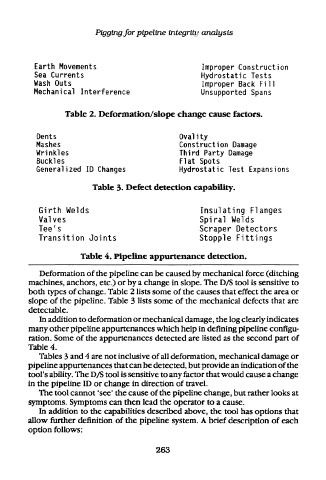

Earth Movements Improper Construction

Sea Currents Hydrostatic Tests

Wash Outs Improper Back Fill

Mechanical Interference Unsupported Spans

Table 2. Deformation/slope change cause factors.

Dents Ovality

Mashes Construction Damage

Wrinkles Third Party Damage

Buckles Flat Spots

Generalized ID Changes Hydrostatic Test Expansions

Table 3. Defect detection capability.

Girth Welds Insulating Flanges

Valves Spiral Welds

Tee's Scraper Detectors

Transition Joints Stopple Fittings

Table 4. Pipeline appurtenance detection.

Deformation of the pipeline can be caused by mechanical force (ditching

machines, anchors, etc.) or by a change in slope. The D/S tool is sensitive to

both types of change. Table 2 lists some of the causes that effect the area or

slope of the pipeline. Table 3 lists some of the mechanical defects that are

detectable.

In addition to deformation or mechanical damage, the log clearly indicates

many other pipeline appurtenances which help in defining pipeline configu-

ration. Some of the appurtenances detected are listed as the second part of

Table 4.

Tables 3 and 4 are not inclusive of all deformation, mechanical damage or

pipeline appurtenances that can be detected, but provide an indication of the

tool's ability. The D/S tool is sensitive to any factor that would cause a change

in the pipeline ID or change in direction of travel.

The tool cannot 'see' the cause of the pipeline change, but rather looks at

symptoms. Symptoms can then lead the operator to a cause.

In addition to the capabilities described above, the tool has options that

allow further definition of the pipeline system. A brief description of each

option follows:

263