Page 285 - Pipeline Pigging Technology

P. 285

Pipeline Pigging Technology

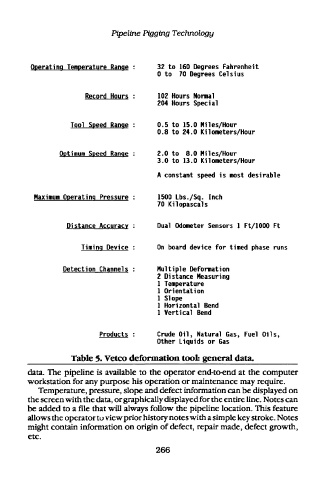

Operating Temperature Range 32 to 160 Degrees Fahrenheit

0 to 70 Degrees Celsius

Record Hours 102 Hours Normal

204 Hours Special

Tool Speed Range 0.5 to 15.0 Miles/Hour

0.8 to 24.0 Kilometers/Hour

Optimum Speed Range 2.0 to 8.0 Miles/Hour

3.0 to 13.0 Kilometers/Hour

A constant speed Is most desirable

Maximum Operating Pressure 1500 Lbs./Sq. Inch

70 Kilopascals

Distance Accuracy Dual Odometer Sensors 1 Ft/1000 Ft

Timing Device On board device for timed phase runs

Detection Channels Multiple Deformation

2 Distance Measuring

1 Temperature

1 Orientation

1 Slope

1 Horizontal Bend

1 Vertical Bend

Products : Crude Oil, Natural Gas, Fuel Oils,

Other Liquids or Gas

Table 5. Vetco deformation tool: general data.

data. The pipeline is available to the operator end-to-end at the computer

workstation for any purpose his operation or maintenance may require.

Temperature, pressure, slope and defect information can be displayed on

the screen with the data, or graphically displayed for the entire line. Notes can

be added to a file that will always follow the pipeline location. This feature

allows the operator to view prior history notes with a simple key stroke. Notes

might contain information on origin of defect, repair made, defect growth,

etc.

266