Page 280 - Pipeline Pigging Technology

P. 280

Pigging for pipeline integrity analysis

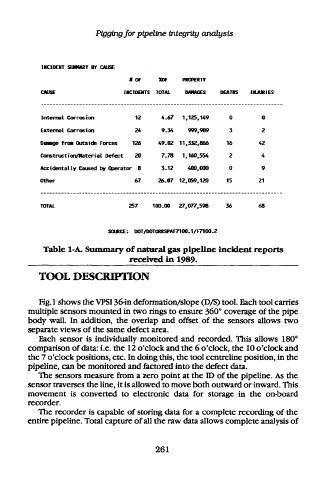

INCIDENT SUMMARY BY CAUSE

# OF XOF PROPERTY

CAUSE INCIDENTS TOTAL DAMAGES DEATHS INJURIES

Internal Corrosion 12 4.67 1.125.149 0 0

External Corrosion 24 9.34 999.909 3 2

Damage fro» Outside Forces 126 49.02 11.332.866 16 42

Construction/Material Defect 20 7.78 1.160.554 2 4

Accidentally Caused by Operator 8 3.12 400.000 0 9

Other 67 26.07 12.059.120 15 21

TOTAL 257 100.00 27.077.598 36 68

SOURCE: DOT/DOTORRSPAF7100.1/F7100.2

Table 1-A. Summary of natural gas pipeline incident reports

received in 1989.

TOOL DESCRIPTION

Fig.l shows the VPSI 36-in deformation/slope (D/S) tool. Each tool carries

multiple sensors mounted in two rings to ensure 360° coverage of the pipe

body wall. In addition, the overlap and offset of the sensors allows two

separate views of the same defect area.

Each sensor is individually monitored and recorded. This allows 180°

comparison of data: i.e. the 12 o'clock and the 6 o'clock, the 10 o'clock and

the 7 o'clock positions, etc. In doing this, the tool centreline position, in the

pipeline, can be monitored and factored into the defect data.

The sensors measure from a zero point at the LD of the pipeline. As the

sensor traverses the line, it is allowed to move both outward or inward. This

movement is converted to electronic data for storage in the on-board

recorder.

The recorder is capable of storing data for a complete recording of the

entire pipeline. Total capture of all the raw data allows complete analysis of

261