Page 305 - Pipeline Pigging Technology

P. 305

Pipeline Pigging Technology

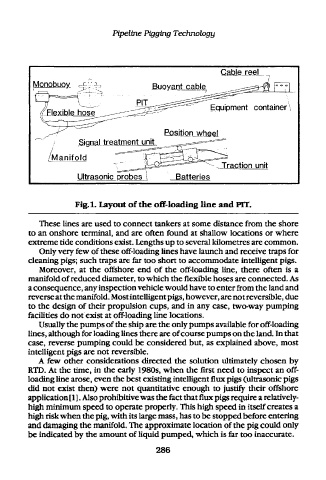

Fig.l. Layout of the off-loading line and PIT.

These lines are used to connect tankers at some distance from the shore

to an onshore terminal, and are often found at shallow locations or where

extreme tide conditions exist. Lengths up to several kilometres are common.

Only very few of these off-loading lines have launch and receive traps for

cleaning pigs; such traps are far too short to accommodate intelligent pigs.

Moreover, at the offshore end of the off-loading line, there often is a

manifold of reduced diameter, to which the flexible hoses are connected. As

a consequence, any inspection vehicle would have to enter from the land and

reverse at the manifold. Most intelligent pigs, however, are not reversible, due

to the design of their propulsion cups, and in any case, two-way pumping

facilities do not exist at off-loading line locations.

Usually the pumps of the ship are the only pumps available for off-loading

lines, although for loading lines there are of course pumps on the land. In that

case, reverse pumping could be considered but, as explained above, most

intelligent pigs are not reversible.

A few other considerations directed the solution ultimately chosen by

RTD. At the time, in the early 1980s, when the first need to inspect an off-

loading line arose, even the best existing intelligent flux pigs (ultrasonic pigs

did not exist then) were not quantitative enough to justify their offshore

application [ 1 ]. Also prohibitive was the fact that flux pigs require a relatively-

high minimum speed to operate properly. This high speed in itself creates a

high risk when the pig, with its large mass, has to be stopped before entering

and damaging the manifold. The approximate location of the pig could only

be indicated by the amount of liquid pumped, which is far too inaccurate.

286